State-of-the-art leather goods production using no-code robotics

Galli SpA, Italy

When robotics is no longer just a matter for experts

THE CHALLENGE

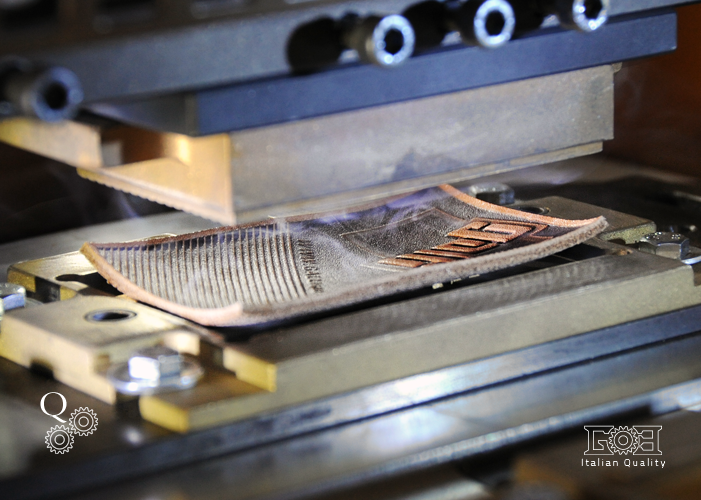

Galli SpA develops innovative systems and machines for the leather goods industry. The leading Italian company offers a large product portfolio for a wide range of applications and supplies individual ma-chines tailored to customer requirements.

For the production of leather goods, numerous work steps are necessary and it is important to guaran-tee a high and consistent quality. Many processes have to be supported or carried out by employees, but often involve very monotonous or unergonomic tasks.

In order to increase productivity and also remain globally competitive, Galli was asked by a customer to develop a customized automation solution that could handle the grinding, polishing and dyeing of the edges of leather pieces, e.g. for belts or bags.

THE APPLICATION

WHY ARTIMINDS

“I can definitely recommend ArtiMinds to anyone who wants to integrate robots into their processes, even if they have little or no programming knowledge. In the run-up, we had also looked at other software solutions, but quickly realized that these were out of the question for us due to the high complexity in programming and for economic aspects.”

ROBERTO VERDUCI

R&D Manager at Galli

THE SOLUTION

Galli did not have any experience and touch points in the implementation of robotics applications up to that point. Therefore, Universal Robots recommended Roberto Verduci, R&D Manager at Galli, to take a look at the programming software ArtiMinds Robot Programming Suite (RPS). He quickly realized what a great time saver and simplifier the intuitive, function block-based graphical programming was. He explains, “The software is so intuitive to use that we didn’t need to take any training.” Thanks to ArtiMinds, Galli was able to complete the project, from design to programming to implementation, without an external integrator.

“ArtiMinds RPS offers a wide range of predefined templates and features that guide and support the programmer to program even complex applications independently. Since the software generates native robot code, one is absolutely flexible at all times and can, for example, also make changes directly on the robot,” explains Verduci.

Thanks to the CAD2Path function of ArtiMinds RPS the problem of varying geometries can be easily solved. Instead of time-consuming teach-in of all points with the robot, (geometrically complex) profiles can be imported from CAD models and the software automatically generates the exact robot path from this. But it is not only this feature that leads to considerable time savings in the programming phase: “Auxiliary functions such as wizards simplify the parameterization of the individual function blocks. Thanks to the 3D simulation environment, it is possible to perform collision and reachability analyses already in the planning phase and in offline mode.”

Robot-based automation of processes previously carried out manually by the operator has increased productivity and produced a consistent quality result that, overall, was even higher than before. The use of robots also has positive effects in terms of personnel resources: Because the operator can now, on the one hand, ensure the smooth operation of the machine without much effort and, in parallel, take care of new and more important processes for which highly qualified know-how is required.

According to Verduci, there is no comparable alternative to the ArtiMinds Robot Programming Suite: “With ArtiMinds, on the other hand, we found a really helpful tool with a convincing price-performance ratio.”

Take Aways of the cobot application:

- No-code robotics: ArtiMinds RPS automatically generates native robot code that runs on the robot manufacturer’s standard controller. This makes it possible to also make changes directly on the robot at any time.

- The graphical, intuitive user interface makes it possible to integrate robots into your own processes even with little or no programming knowledge.

- Offline programming: use CAD files to automatically create tool paths for complex geometries, perform collision and reachability tests, and calculate collision-free paths.

- Auxiliary functions such as wizards simplify the parameterization of the individual function blocks.

- Online support: The experts of ArtiMinds support the user in all phases of a robot application, if required.

GET STARTED AND LEARN MORE IN A FREE ONLINE DEMO

In just a few minutes, we will show you how to plan, program, operate, analyze and optimize robot applications cost-efficiently, intuitively and easily with ArtiMinds RPS.

The non-binding free online demo is the perfect way to get a first impression of the software, the application portfolio and if it suits your needs.

MUCH MORE THAN JUST SIMPLE ROBOT PROGRAMMING: With RPS you create cross-process standardization – from planning and programming to maintenance.

We answer the most important questions about the ArtiMinds software solutions, applications and the company in our FAQ section.

Program and simulate robot applications independent of manufacturers, reduce maintenance costs and alleviate the lack of skilled workforces. Find out how ZF succeeds thanks to ArtiMinds!