Cable Assembly, Processing and Handling

Picking, guiding and inserting cables, wires or connectors using robots

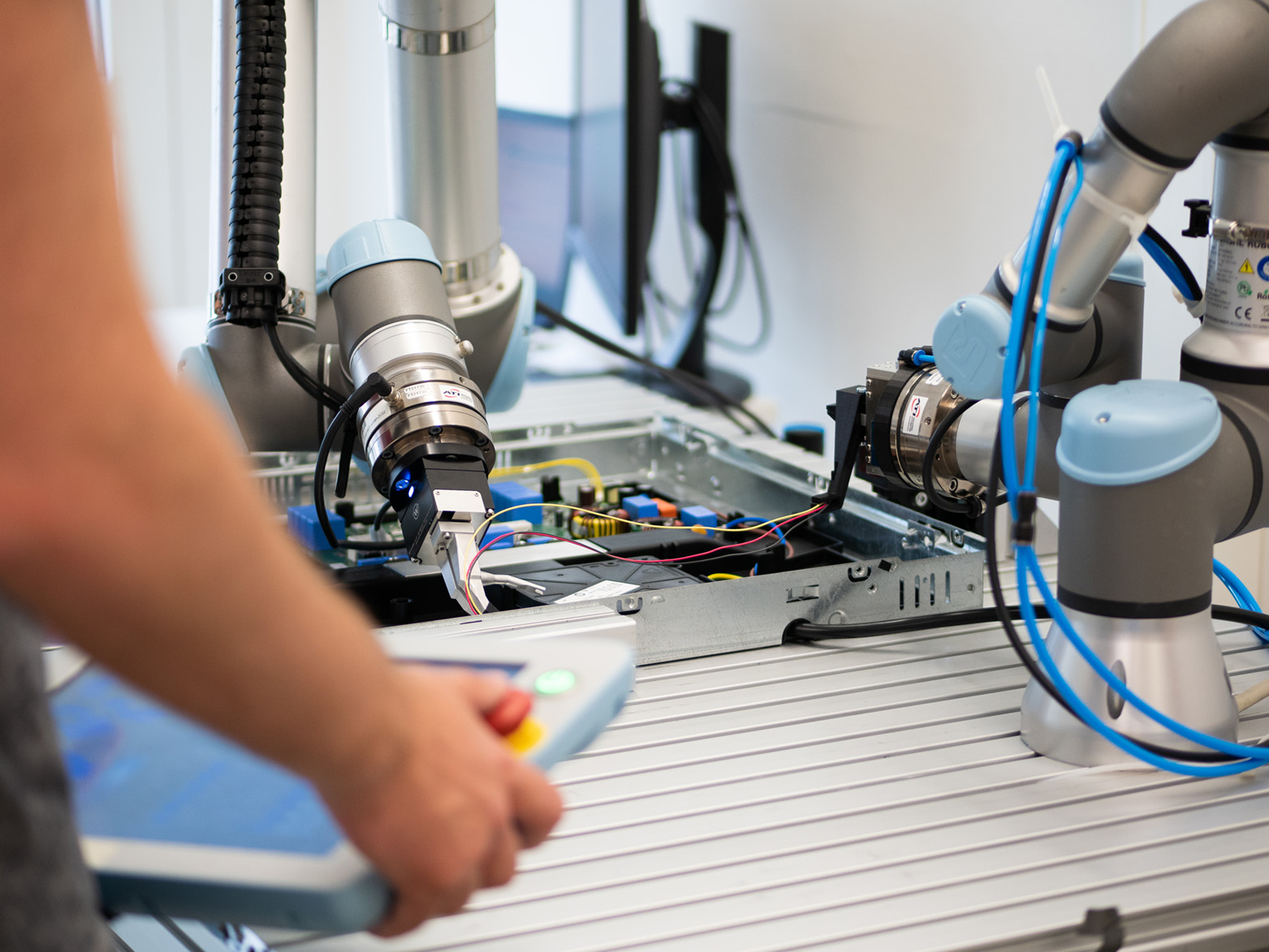

Variances, i.e. deviating geometries or positions of components or changing products on the lines, make it difficult to automate certain production steps. Therefore, the assembly and handling of flexible and limp components such as cables, wires or connectors could not be automated economically with conventional automation until now. With ArtiMinds RPS software, robots can now precisely detect, grip and insert flexible and sensitive components such as cables, connectors or contacts.

Forces and deviations can be analyzed with ArtiMinds LAR in order to optimally adapt movements and joining processes to the requirements of the workpiece and given frame conditions, to shorten cycle times and thus optimizing production.

Automation as a challenge

Labour shortage, rising wage costs, the demand for more digitalization and traceability, as well as topics such as reshoring and geopolitical challenges pose major challenges for many industries. The solution appears to be the increasing automation of production steps and processes.

The automotive industry in particular faces a high pressure to automate, as there are also wire harness-specific challenges such as the miniaturization of cables, plugs and connectors as well as a high number of variants due to customer-specific cable harnesses combined with high quality requirements set by OEMs.

Robots offer greater flexibility in terms of possible applications and changeover than large special machines, and also offer the advantage of manageable acquisition costs and smaller space requirements. By parallelizing processes with several robot cells, the desired quantities and cycle times can also be easily achieved. By means of force control, robots achieve the required sensitivity with high process stability, as they are able to always join or insert pieces with a constant desired force, so that even sensitive contacts are not damaged.

In addition to the actual processing and assembly process, robots can also provide optimum support during cable or wire feeding and relieve the strain on humans, e.g. when feeding heavy high-voltage cables.

Smart cable processing and wire harness assembly

Automated handling, manipulation, and assembly of flexible workpieces such as cables, wires, connectors or fabrics/coverings pose a number of challenges in production. Conventional robotic processes often lack the dexterity to handle these sensitive materials. Localizing the position and identifying the the shape of parts are a major challenge in classic robot programming. The liability and form instability of the material leads to constantly changing dynamics of the part tolerances, shape, and localization throughout the entire handling or assembly process. However, robot-based, precise cable assembly can be programmed and implemented robustly and efficiently, and therefore economically, using ArtiMinds RPS. The complexity of programming automation processes with tolerances becomes manageable with ArtiMinds.

Find out in our current webinar special “Robot-based automation – cables completely under control” which solutions are already available for the handling and assembly of cables, wires and connectors and how you can flexibly compensate for variances and tolerances (>register now free of charge).

You need support in automating the handling and assembly of cables? At ArtiMinds you get software & project support from a single source!

You would like to implement a robotics project? Use our free robotics checklist to select the right hardware & software and to organize the most important project steps!

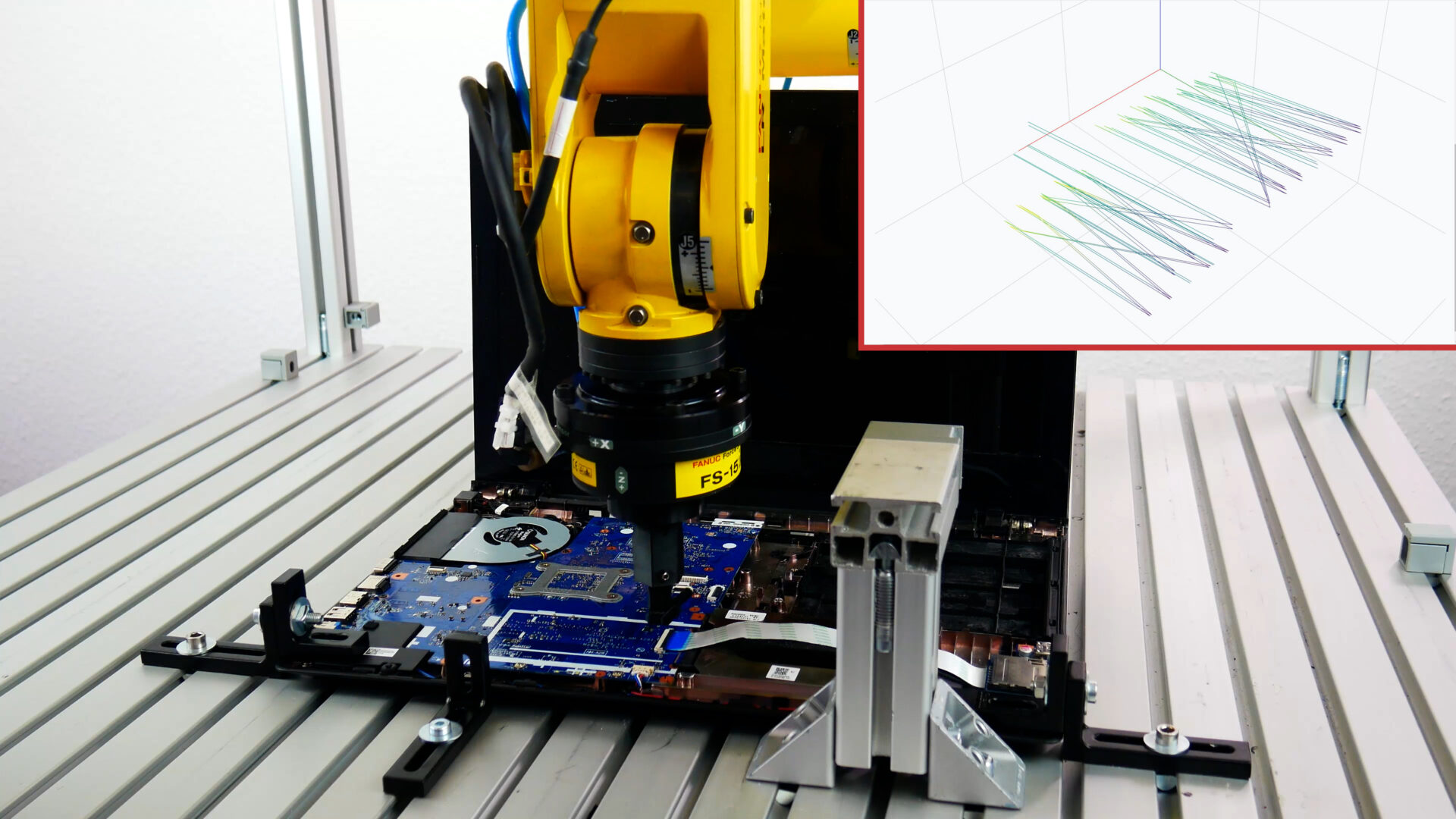

Application Example: Laser-based Cable Assembly

During wire harness assembly or cable harness production, flexible cables must be gripped, processed and plugged into a connector housing, for example. Automating this plugging process with robots is not possible without sensor technology or force control and furthermore is very complex and usually not robust with conventional programming. If the cables or wires hang freely in the room, even the first step, picking the parts, is a major challenge.

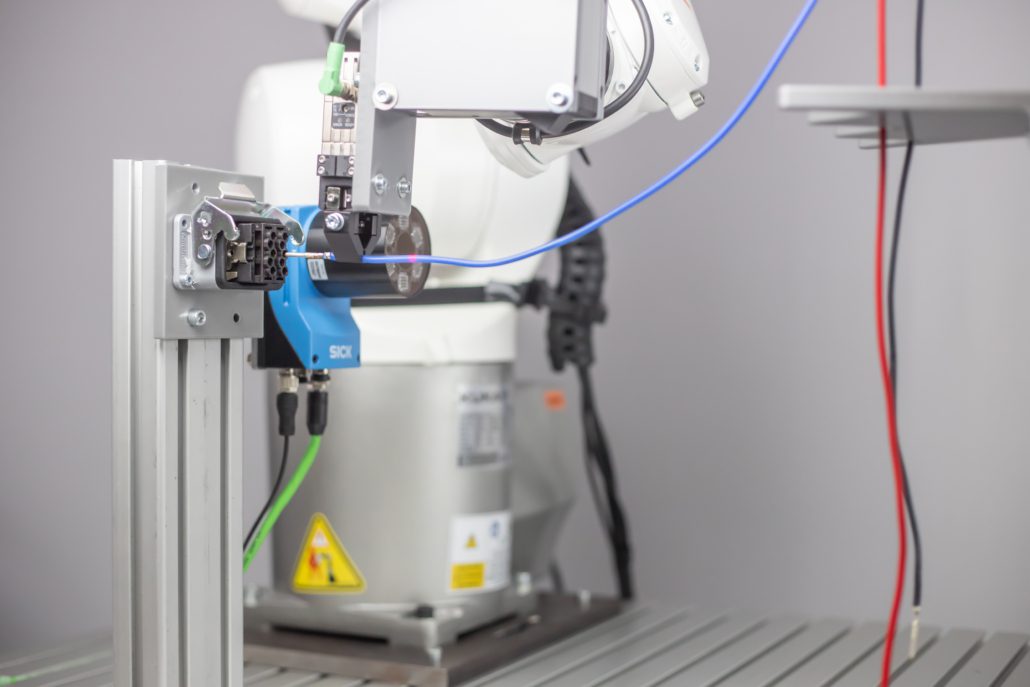

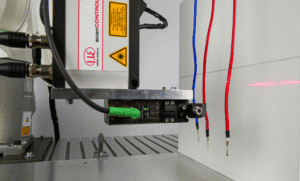

The smart robotic approach developed by ArtiMinds for this complex cable handling application is based on a unique combination of laser line scanners, 2D camera technology and force-torque measurement, as well as interfaces and intelligent function blocks in the ArtiMinds Robot Programming Suite (RPS), which were newly developed for this purpose.

The software processes the scan result in real time and synchronizes it with the robot motion to determine the exact pickup point. It then performs a force-controlled joining operation that enables precise and safe insertion of the cables into the connector housing. During the final pull test, the robot checks whether the cable end is correctly engaged in the housing.

Application Example: Ribbon Cable Assembly

Flat ribbon cables are used for signal transmission in modules in electronics manufacturing as they save space, time and thus money. However, handling the dimensionally unstable and sensitive cables is difficult due to their low stiffness and requires a great deal of dexterity. By means of force-torque control, new areas of application can be opened up for industrial robots that cannot be implemented with realistic effort using conventional programming.

The “Spike Search” function template of ArtiMinds RPS automatically compensates for tolerances during the insertion process. That is, in order to find the correct insertion position, the robot performs a force-controlled search movement and attempts to insert the cable into the socket. As soon as a defined insertion depth is registered by the robot, it knows that it has found the socket and robustly inserts the flexible component at this position. A tensile test then ensures that the cable is correctly seated.

Further application examples:

- Assembly of high-voltage plugs and heavy high-voltage cables

- End-of-Line testing and tensile tests

- Covering of car seats

- Wire harness production and assembly

- Wiring of switch cabinets

- Gripping and placing cables in cable trays

- Crimping

- Routing

You want more? We support you in the robot-based automation of your cable assembly

You want more? We support you in the robot-based automation of your cable assembly

You want to integrate new and flexible automation processes into your workflows and need e.g. support in automating cable handling and assembly processes or cable production? Our Automation Engineering team of engineers and robotics experts will be happy to advise you and take over tasks such as the prototyping.

ArtiMinds is a leader in the development of innovative and sophisticated robot automation solutions, whether as a partial or overall concept. Our experts will be happy to provide you with advice and support from conceptual design to implementation.

Get in touch – our specialists will provide you with comprehensive advice and develop an initial concept or carry out a feasibility study in close cooperation with you.

Industrial examples – short videos of real customer applications

ARTIMINDS – YOUR HOLISTIC ROBOTICS PARTNER

OUR OFFERING:

Link to: Robot Programming Software

ROBOTICS SOFTWARE

Link to: Consulting & Engineering

ROBOTICS ENGINEERING

Why ArtiMinds Robotics?

The template library of ArtiMinds RPS with over 60 templates covers all conceivable movements, processes and operations. Thanks to the intelligent algorithms, force-controlled applications, for example, can be programmed without any problems. With ArtiMinds you are one step ahead. Talk to our robotics experts about your automation project and smart solutions for the handling and assembly of cables, connectors and contacts – we will be happy to support you!

>>BLOG ARTICLE: ArtiMinds RPS & LAR at a glance

Highlights of ArtiMinds RPS for handling and assembling cables & connectors:

- Easy integration of force-torque sensors, grippers, vision systems and laser scanners

- Force-controlled, precise gripping and insertion of flexible materials such as cables, wires or connectors

- Automatic compensation of variances and shape instabilities

- Fast changeover and flexibility with different variants

- Robust and economical assembly of connectors and cables

Choose a robot-based flexible automation solution – choose ArtiMinds. See for yourself in an online demo!

>>THAT´S WHAT OUR CUSTOMERS SAY<<

Just get in touch. Our application experts will be happy to advise you on your individual automated robot application. Make an appointment right now for an online demo and learn how ArtiMinds can help you to implement a flexible robotic automation project.

Browse through our Robotics Blog or FAQ section and learn interesting facts about ArtiMinds RPS & LAR. Our Download & Press area provides further information. Or sign up to our newsletter for regular news and ongoing updates.

FREE ONLINE DEMO: GET STARTED AND LEARN MORE ABOUT ROBOT-BASED AUTOMATION

In just a few minutes, we will show you how to plan, program, operate, analyze and optimize robot applications cost-efficiently, intuitively and easily with ArtiMinds RPS.

The non-binding free online demo is the perfect way to get a first impression of the software, the application portfolio and if it suits your needs.