Robotics Blog Powered By ArtiMinds

Industry Topics, ArtiMinds News & Robotics Trends

October 21, 2024

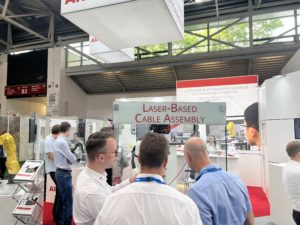

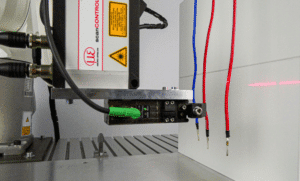

ArtiMinds showcases sensor-based assembly and process data analysis at SPS 2024

At SPS – Smart Production Solutions in Nuremberg in Hall 7a, Stand 141, ArtiMinds Robotics and LMI Technologies will be presenting an advanced robotic automation solution for sensor-based assembly of cables and connectors as well as new possibilities for process data analysis with ArtiMinds LAR.

We have a limited contingent of free day passes for your visit to the trade fair. Simply send us a short email to receive your ticket.

October 16, 2024

Secure subsidies: International robotics funding programs

We show which robotics funding programs are currently available, what projects are funded and to what extent, and how you can apply.

October 1, 2024

Release of ArtiMinds RPS 1.30

The latest ArtiMinds RPS version 1.30 is now available for installation.

The update includes new integration and support for additional robot models from ABB and KUKA as well as laser scanners from the manufacturers Micro-Epsilon (scanCONTROL), LMI Technologies (GOCATOR) and Keyence (LJ). In addition, programming with 3D points has been expanded and improved.

As always, you can find the entire change log with all changes and bug fixes in the ArtiMinds RPS directory.

The release is available via download or online update.

September 25, 2024

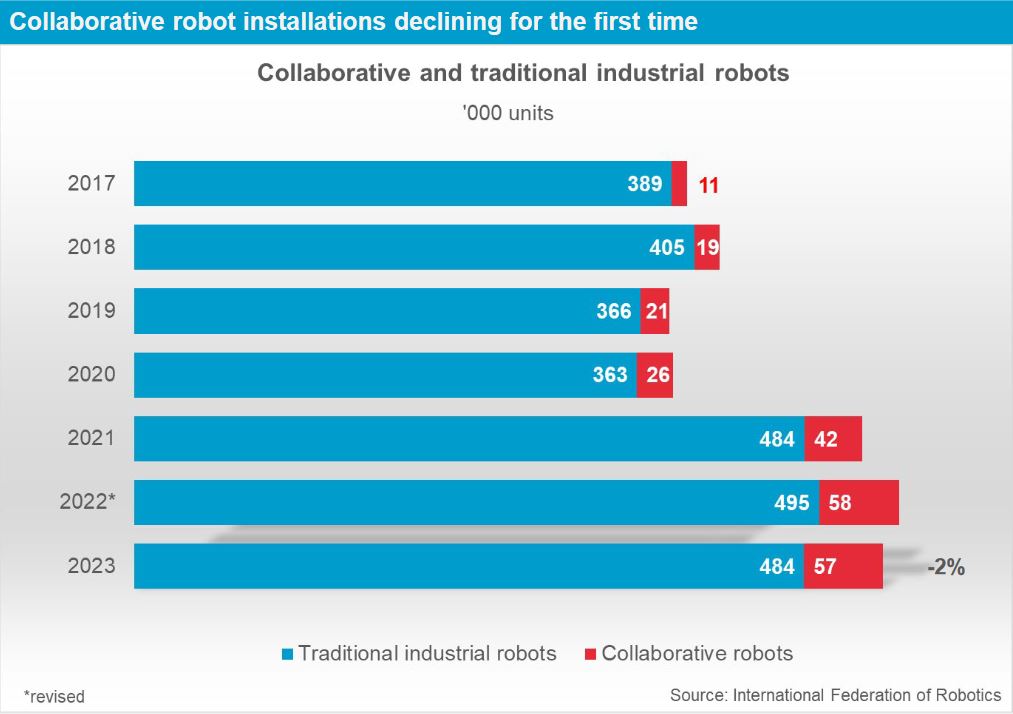

IFR: Record of 4 million robots worldwide

The new World Robotics Report published by the global association IFR recorded 4,281,585 industrial robots in factories worldwide. In Europe the operational stock reached a new record of 269,427 units. Installations in Germany, the largest European market and the only European one in the global top five, were up 7% to 28,355 units. Strong robot industries in this country are the automotive industry and the metal industry.

However, installations in the second largest European market, Italy, fell by 9% to 10,412 units. The third-largest European market, France, even recorded a drop of 13%, with 6,386 units installed. In the UK, on the other hand, a total of 3,830 industrial robots were installed – a significant increase of 51% compared to 2022. The main driver was investment by the automotive industry, mainly in assembly.

Exciting: after years of growth, the cobot share of the overall robot market is stagnating at around 10%. Is the big cobot boom over?

September 23, 2024

Myth Check: Cobots vs. Industrial Robots

Despite cobots being valued in the industry for their adaptability and ease of use, Automation 4.0 shows that conventional industrial robots offer significant advantages, especially for small and medium- sized companies.

This leads to our myth check cobot vs. industrial robot: What are the advantages and disadvantages for SMEs? Which robot should you choose?

Here is the answer!

September 11, 2024

3 Questions to… Sven Kiesser

Who are the people shaping robotics at ArtiMinds every day? In our “3 Questions To…” series, we reveal more about the team and introduce the faces behind the scene.

Today we are speaking with a true ArtiMinds veteran: Sven Kiesser. With nearly a decade of experience, he knows RPS inside and out. As a key member of both software development and technical support, he values his dual role for its advantages. Many customer inquiries demand deep technical knowledge to address complex questions and issues effectively, ensuring quick and detailed responses.

1. What do you enjoy most about your work?

That is absolutely the variety! I often have to familiarize myself with new problems and develop innovative solutions. This requires continuous development of my skills and allows me to constantly learn new things. True to my motto: “If something is too complicated, learn it.” Furthermore there’s the great team I work with. I particularly appreciate our lunch breaks together, where we talk and laugh a lot, even outside of work-related topics.

2. What does a typical working week look like for you?

In my role as software developer, I am guided by our backlog and the feature list for the next release, using classic software development processes. Customer problems always take priority, which means that my working week often has to be flexible. This approach allows us to respond quickly and effectively to customer requests while continuously improving the software. This means that if a bug occurs or there is a feature request, these can be dealt with immediately by me or the development team.

3. What do you do to balance your professional life?

In recent years, I’ve become a big fan of long-distance hiking, Te Araroa trail for example, and photography. Through both, you focus very strongly on things completely away from everyday life and constantly discover and learn new things, which helps me to clear my head.

August 20, 2024

Why does the use of robots fail?

Automation 4.0 is the answer to current challenges such as cost pressure, skilled labor shortages, strained supply chains and digitalization. Companies face the task of making production processes economical, efficient, and at the same time attractive and ergonomic for employees. Flexible automation solutions with robots are in demand for this purpose.

But how can robots be successfully integrated into industrial processes, and what is crucial to unlocking their full potential?

Our latest blog post highlights the key factors for successful Automation 4.0.

August 12, 2024

Robotic Automation: free Consulting

Would you like to increase the level of automation in your production and automate production processes with robots or optimize existing robot applications?

Take advantage of the free initial consultation with one of our robotics experts, in which we will take a close look at your processes, identify the potential of robot automation in your production and work with you to evaluate new ideas for cost-effective implementation.

Let´s get in touch to discuss your needs in detail.

July 31, 2024

Robots without Feeling

While humans can see and feel thanks to their eyes and hands, robots do not have these abilities per se. A decisive factor in being able to exploit the full potential of industrial robots is therefore the use of highly developed sensors in combination with intelligent software that enables data processing and evaluation.

In this blog post, we take a look at the wide range of possibilities and applications this opens up for robots.

July 29, 2024

Release of ArtiMinds RPS 1.29

The latest ArtiMinds RPS version 1.29 is now available for installation.

The update includes the new integration and support for the ABB cobot model GoFa 12 and the KUKA robot model KR22 R1610-2. In addition, it is now possible to open multiple instances of ArtiMinds RPS simultaneously and the new “Move Linear to Displayed Point” function is available.

As always, you can find the entire change log with all changes and bug fixes in the ArtiMinds RPS directory.

The release is available via download or online update.

July 20, 2024

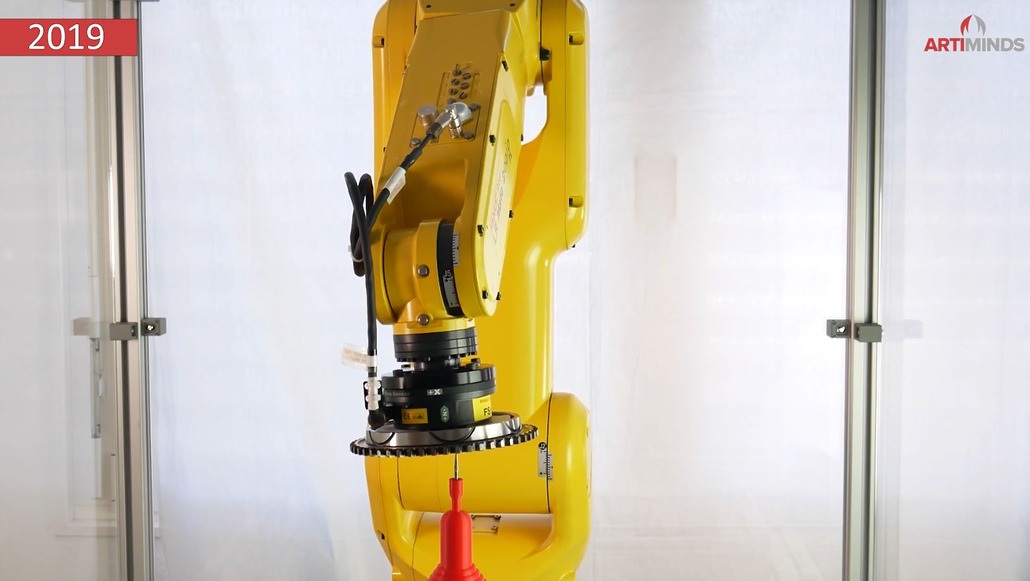

All trade show robot demonstrators from the last 8 years at a glance

In 2024, ArtiMinds Robotics celebrated its 11th anniversary. It´s the perfect time to reflect on the developments of the past few years.

And what better way to do so than by looking back at the trade show robot demonstrations from the past eight years (2015-2023)?

Enyoy this little journey through time.

July 10, 2024

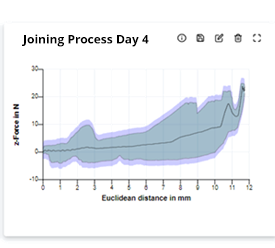

NEW: LAR Standalone for existing systems and plants

ArtiMinds LAR (Learning & Analytics for Robots) has become indispensable as a data analysis and optimization tool in programming robot systems. Now, it is also possible to retrofit deployed robots or existing systems that have not been programmed with ArtiMinds RPS for data acquisition with ArtiMinds LAR (“LAR Standalone”).

This makes it easy to analyze and monitor robot processes, for example, to intervene at an early stage in the event of drifting positioning and stabilize the process or to carry out data-based optimizations.

Do you have processes that regularly cause problems and error cases? Contact us, and we will be happy to advise you personally on the integration and use of LAR Standalone.

June 17, 2024

Release of ArtiMinds RPS 1.28

The latest ArtiMinds RPS version 1.28 is now available for installation.

The update includes the latest integrations of the ABB robot model GoFa CRB 15000, all ABB robots with OmniCore controller version, the FANUC robot model CRX-25iA as well as the support of the force functionality for CRX cobots. In addition, it is now possible to use Via-Points that are computed during program runtime (Move Circular Template) and there are extensions to the CAD2Path feature.

You can find the entire change log with all changes and bug fixes in the ArtiMinds RPS directory.

The release is available via download or online update

June 11, 2024

3 Questions to… Nicolas Sigonney

Who are the people who are shaping robotics at ArtiMinds every day? The format “3 Questions to…” reveals more and introduces the faces behind the team.

Today we are talking to Nicolas Sigonney, who has been part of the Automation Engineering team since 2019. His main task is to develop automation solutions for industrial processes. As everything at ArtiMinds revolves around robotics, this naturally involves robot automation and applications that need the integration of a PLCs, force-torque sensors, cameras and/or grippers.

1. What do you enjoy most about your work?

I find the variety of my tasks very exciting because I deal with the conception, implementation and validation of automation solutions. There are always different ways to solve an automation project. It motivates me to see after project completion that the ideas and approaches work as planned and that each development step is an important piece of the puzzle for a successful end result.

2. What does a typical working week look like for you?

At the beginning of the week, there is a regular internal team coordination meeting to discuss the status of ongoing projects. For active projects, I then have individual meetings with clients to present them the progress and milestones. According to the deadlines and specifications to be met, I spend the remaining time working on the customer projects and developing and validating suitable automation solutions.

3. What do you do to balance your professional life?

I regularly play basketball in a recreational team and try to explore the underwater world by scuba diving. Apart from that, I’m a family person and love spending time with them.

June 5, 2024

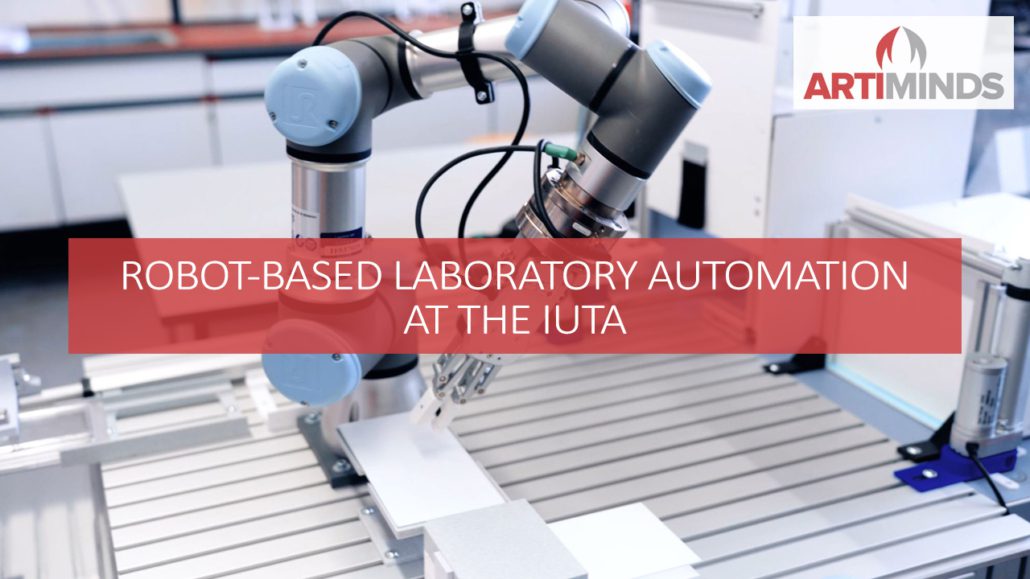

Laboratory Automation With ArtiMinds at IUTA

In the analytical laboratory, numerous analysis processes continue to be executed manually. To change this, the German Institut fuer Umwelt & Energie, Technik & Analytik (IUTA) set itself the goal of developing a flexible robot-based automation concept that could be implemented by the laboratory staff themselves.

Thereby, the team therefore relied on the intuitive and manufacturer-independent software solution ArtiMinds Robot Programming Suite to program the robot.

April 30, 2024

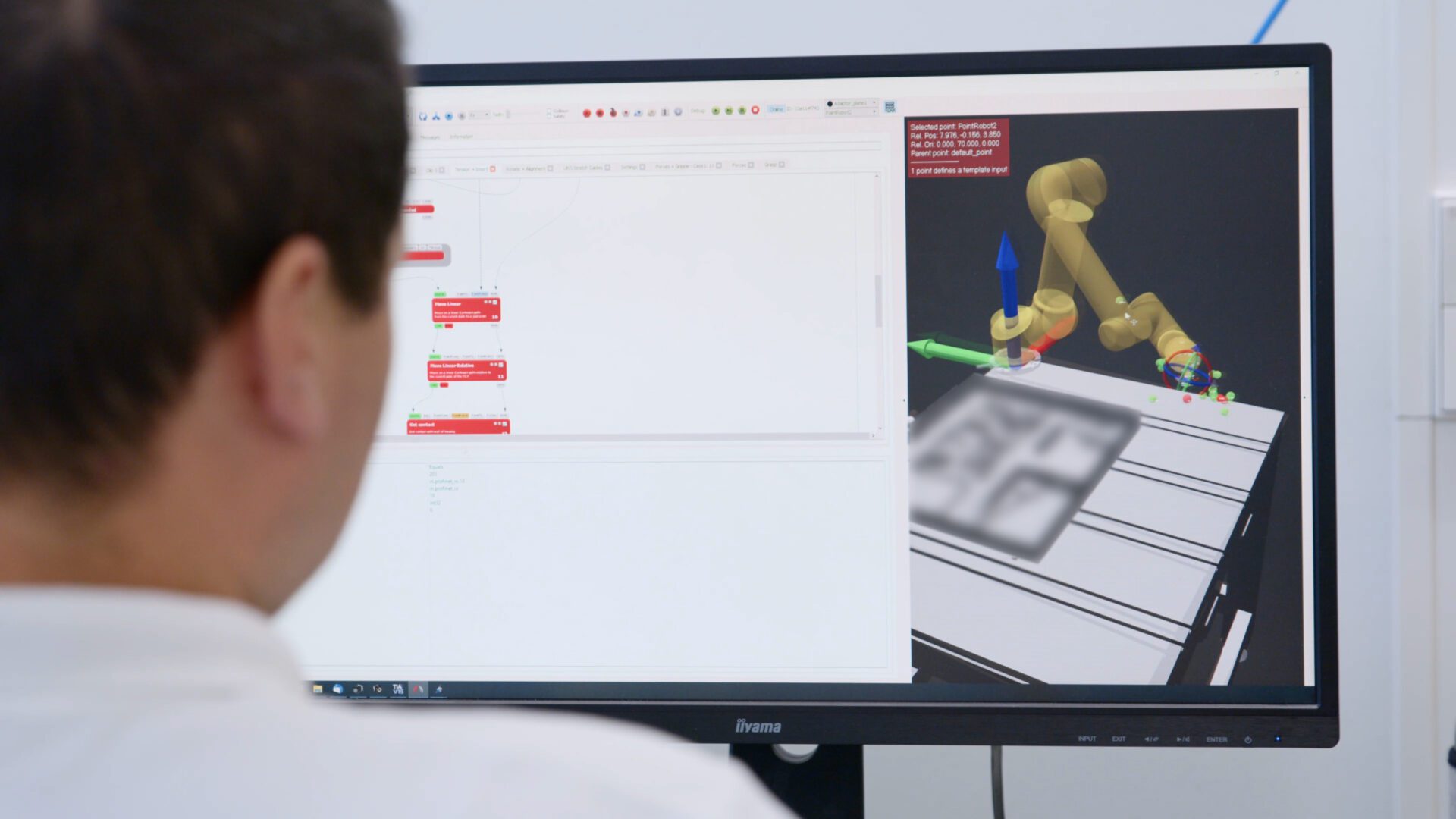

AI-based automation of engineering for industrial robot applications

If you missed the ArtiMinds presentation at the last Hannover Messe, you can now watch the video recording. Dennis Nocke talked about how AI-based methods can facilitate the programming of industrial robot applications and how engineering can be automated step by step. With the increasing use of sensor-adaptive automation processes, especially with robots involved, the complexity for the system programmer increases. In addition to creating complex program structures, parameterization in particular becomes a challenge.

Correlations between setting options and the quality of the result are becoming more difficult to grasp. The presentation shows current developments in how existing processes can be expanded using AI-based methods using the example of robot applications in order to achieve automation of engineering with little effort and a significant increase in efficiency.

April 12, 2024

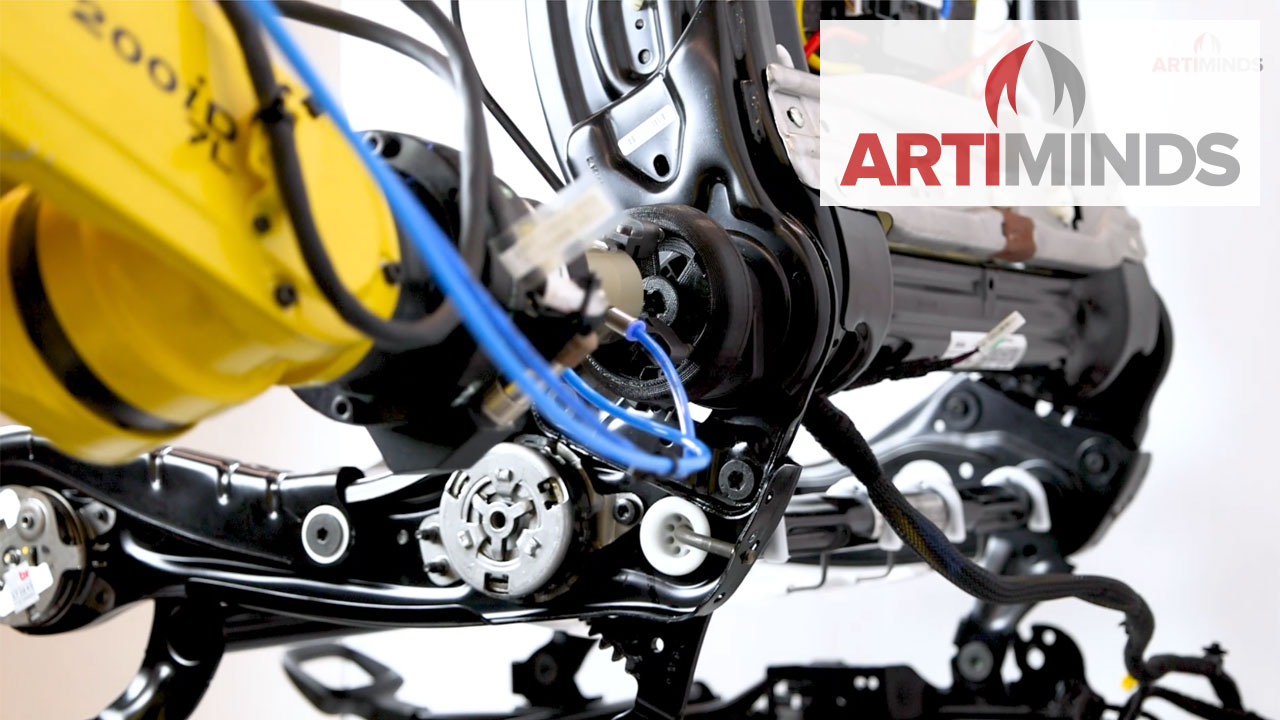

Robotics Challenge: ArtiMinds receives award for robot-based cable assembly

To promote automation in wire harness assembly, the Transformation-Hub Leitungssatz (Wire Harness) has launched the Robotics Challenge 2024.

The task of the Robotics Challenge represented a challenging automation problem in wire harness assembly: the robust handling of flexible components such as cables and connectors with tolerances.

The processing steps included identifying and feeding a socket housing into a holder in the correct position, inserting various contact parts into the socket housing according to a specified configuration and ensuring that the contacts are correctly latched in the end position.

ArtiMinds has received the award for best economic efficiency for the robot solution it developed. In addition to the technological approach and process reliability, the jury was particularly impressed by the extremely short cycle time of less than 5 seconds per cable insertion process compared to the competition.

April 3, 2024

Visit ArtiMinds at the Application Park Robotics at Hannover Fair

Robotics is a key theme at this years HANNOVER FAIR. Robots of all shapes and sizes – from industrial robots and cobots to autonomous mobile robots – are on display throughout the exhibition grounds. A special highlight is the Application Park in Hall 5, where experienced robotics companies and start-ups in particular will be demonstrating the wide range of applications for robots and the interaction between humans, machines and artificial intelligence. Partner of the Application Park is the German Robotics Association (DRV).

You will find ArtiMinds at the Application Park in hall 5 at booth B28-11. Get a free ticket for your visit.

March 15, 2024

3 Questions to… Florian Geike

Who are the people who are shaping robotics at ArtiMinds every day? The format “3 Questions to…” reveals more and introduces the faces behind the team.

We start the year with Florian Geike. Florian, who will be celebrating his two-year jubilee at ArtiMinds in a few days, is an Insides Sales Manager and forms the important interface between technology, sales and administration. The core of his work is the preparation of technical project proposals in collaboration with our Automation Engineering team. At the same time, he deals with issues such as contract reviews, reporting and traditional order processing and follow-up. And how does he describe himself in three words? Correct, sarcastic, open-minded – sounds like an exciting mix:

1. What do you enjoy most about your work?

I work closely with our project and software engineers, particularly when preparing technical offers, and transfer their ideas into commercial offers and service descriptions, i.e. I always work directly on the technological pulse of ArtiMinds. Originally having only a commercial background, this gives me the opportunity to acquire new knowledge in the field of robotics every day. This is challenging, but has great advantages. It makes my daily work in this demanding environment easier, so that I can work independently on my own external customer projects and also support the sales team at trade fairs.

2. What does a typical working week look like for you?

The working week is packed with a wide variety of internal and external appointments. I can’t plan ahead for individual days in the long term. I have to react quickly to requirements and familiarize myself with new projects. A plan that was still in place last Friday may no longer be valid the following Tuesday. Jumping between countless topics and issues is challenging, but I personally really enjoy it.

3. What do you do to balance your professional life?

I love playing snooker and am also a volunteer member of the board of Snookerclub 147 e.V. in Karlsruhe. I am also a sport manager and represent the interests of our athletes to the state and national associations. On the one hand, my training program is a balance after work during the week. On the other hand, I often travel around the country at weekends for leagues and tournaments.

February 27, 2024

Release of ArtiMinds RPS 1.27

The latest ArtiMinds RPS version 1.27 is now available for installation.

The update includes the new integration and support of the UR20 robot model and MicroEpsilon laser scanner for KUKA, new templates for working with laser scanners (as part of the vision template family) and improved options for creating paths on CAD model surfaces.

You can find the entire change log with all changes and bug fixes in the ArtiMinds RPS directory.

The release is available via download or online update

January 11, 2024

Don´t miss: ArtiMinds at all about automation trade show in Friedrichshafen

The new year is just 11 days old and we already have our first trade fair announcement for you:

We cordially invite you to all about automation in Friedrichshafen on March 5 and 6, 2024. At the trade show, you will experience systems, components, software and engineering for industrial automation and industrial communication.

Get your free ticket and visit us at our booth B2-150, right next to the German Robotics Association (DRV).

December 15, 2023

Artiminds` X-mas Greetings

As the end of the year approaches, it’s a good time to look back on the current year and look forward to the year ahead.

In his personal Christmas greetings, ArtiMinds co-founder and CEO Sven Schmidt-Rohr explains what made 2023 an exciting year for him and why he believes it is so important to dare transformation on the road to the future.

December 15, 2023

Release of ArtiMinds RPS 1.26

The latest ArtiMinds RPS version 1.26 is now available for installation.

The update includes, among other things, The update includes the integration of the Fanuc robot model M-10iD/16S, a new function in all wizards to switch between teaching with the real and teaching with the virtual robot as well as improved performance of simulation, compilation and loading of project loading and the automatic enabled data streaming to ArtiMinds LAR after loading a project.

You can find the entire change log with all changes and bug fixes in the ArtiMinds RPS directory.

The release is available via download or online update.

November 30, 2023

That´s what our customers say

ArtiMinds’ software products for robot automation are used by our customers in a wide variety of applications: from mechanical assembly, surface processing or quality control to laboratory automation.

Our robotics engineering services, with which we support our customers individually, are just as diverse as the application sectors.

What especially do customers value about our expertise? And why do they no longer want to program robots without ArtiMinds?

In this video they will tell us.

November 20, 2023

3 Questions to… Roman Klingl

Who are the people who are shaping robotics at ArtiMinds every day? The format “3 Questions to…” reveals more and introduces the faces behind the team.

Today, our Sales Director Roman Klingl is our interview partner. He describes himself as an active, communicative and purposeful person, so he definitely has the ideal qualities for his position at ArtiMinds. His current focus lies on expanding the sales team and implementing a scalable sales structure. He is happy being able to count on the know-how and support of his team at all times.

1. What do you enjoy most about your work?

My motto is “Think in solutions!”. That’s why I love working with people who have the desire to make a difference. And that is definitely the case at ArtiMinds. Every day, together we turn ideas into reality and unleash positive change.

2. What fascinates you about your job?

I am fascinated by the fact that we are operating in a highly dynamic future market. It’s not just about simple robotics, but about the demanding challenge of making sensor-adaptive robot applications “fly”. This requires a high degree of technical finesse and is anything but trivial. However, with our innovative software products, our experts manage to make this complexity manageable for customers. That is something that truly excites me.

3. What do you do to balance your professional life?

To find a balance, I like to retreat for walks in the forest or the mountains. These moments, together with my wife and our dog, allow me to clear my head and recharge my batteries.

November 10, 2023

Release of additional dates for the Webinar “Cables completely under control”

Due to the high demand for our current webinar series on “Robot-based automation in the field of cable handling and assembly”, we have just put two additional dates online.

The first two sessions on November 8 & 21 were fully booked within a very short time.

We are therefore offering two additional dates on November 16 at 3 pm and November 21 at 11 am (CEST).

What is the webinar about?

When flexible parts such as cables, wires or connectors are involved automating assembly processes can be a real challenge.

In this new free of charge webinar series our application experts explain why and, above all, how sensor-adaptive robotics plays a key role in automated cable processing and wire harness production.

Furthermore, we will show what automation solutions are already available on the market for handling and assembling cables, talk about what cost savings can be expected, and how an efficient and economically profitable implementation can be achieved by using robots.

November 6, 2023

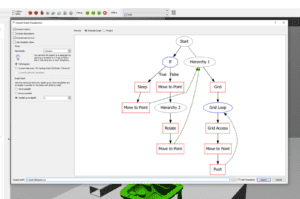

TechTip: Graphical Export of a robot program

When programming complex processes, it can sometimes become quite confusing, especially when templates in ArtiMinds RPS are organized by hierarchies.

In order to still be able to keep track of the program, there is now a new function called ‘Program Visualization’! With it, you can either effortlessly visualize the flow of individual program sections, i.e. sub-processes, or even create a comprehensible overview of the entire program and export it graphically.

How to perform a program visualization and which options you can set is revealed in our current TechTip.

October 25, 2023

How to handle the shortage of skilled workers

The shortage of skilled workers has become a burning issue in recent years. The problematic situation affects almost all industries and threatens the countries` economic growth and innovative strength.

The use of robots, i.e. robotization, is increasingly being proclaimed as a viable solution for the future.

But do robots really help to address the shortage of skilled workers?

October 15, 2023

Research project RoboGrind: Successful Project Completion

Almost two years ago, the RoboGrind research project was launched with the aim of ensuring long-term sustainability in the remanufacturing of worn components of green technologies, such as wind turbine rotor blades. To achieve this, an AI-based, flexible automation solution for robotic surface processing was to be developed.

At the end of September the project was successfully completed as planned. Therefore we have created a final video to present the research results.

October 12, 2023

Upcoming Webinar Special Edition: Cables completely under control

Reducing manual labor, increasing automation: when it comes to flexible parts such as cables, wires or connectors, many companies have a hard time.

In this new free webinar series our application experts explain, what kind of industrial automation solutions for the handling and assembly of cables already exist, what cost savings are possible, why robots in combination with sensors play a key role and how applications can be implemented efficiently and economically profitable.

The webinar special edition starts on November 08.

September 9, 2023

Meet ArtiMinds at Motek in Stuttgart

From October 10 to 13, Motek will be held together with Bondexpo in Stuttgart. The focus is on industrial production as a complete system. The trade fair maps the complete process chain for economical production and assembly automation.

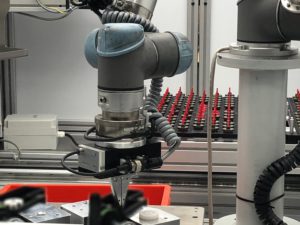

At our booth 7103 in hall 7 with our partner next robotics, we will show how ArtiMinds RPS and LAR support the robot-based automation of gripping and inserting flexible cables.

You would like to talk to our automation experts at Motek, but don’t have a ticket yet? Use the following button to register directly for your free day pass!

August 22, 2023

Release of ArtiMinds RPS 1.24

The latest ArtiMinds RPS version 1.24 is now available for installation.

The update includes, among other things, the integration of new robot models from Kuka and Fanuc, as well as software enhancements like a new export functionality “Program to Visualization” for creating a flowchart of the logical program structure and a new popup editor for quickly changing the template tool.

You can find the entire change log with all changes and bug fixes in the ArtiMinds RPS directory.

The release is available via download or online update.

August 16, 2023

3 Questions to… Oliver Karrenbauer

Who are the people who are shaping robotics at ArtiMinds every day? The format “3 Questions to…” reveals more and introduces the faces behind the team.

Today, Oliver Karrenbauer is our interview partner. True to his motto “No problem is too hard to solve”, the software developer, who describes himself as reliable, analytical and persistent, especially loves challenging customer projects. He has been part of the team for more than seven years and is responsible for making it easier for our customers to work with robots.

1. What fascinates you about your job?

What fascinates me most are the different robot systems and the diverse applications that we solve for our customers. Every day is different and brings new challenges to overcome.

2. How does a typical work week look like for you?

A typical work week can be very varied. Sometimes I am in close direct exchange with our customers to implement specific software solutions. On other days, I focus on developing new features in our ArtiMinds RPS software or work intensively on solving difficult problems. Every week brings new tasks and challenges, which makes my workday exciting and dynamic.

3. What do you do to balance your professional life?

I like to put on my sports shoes to go running. Whether to relax or to prepare for an upcoming marathon, running helps me clear my head and recharge my batteries.

August 3, 2023

Visit ArtiMinds at Deburring Expo

Deburring Expo, the leading trade fair for deburring technologies and precision surfaces, will take place from October 10 to 12 in Karlsruhe. At our joint booth with SHL Automatisierungstechnik in hall 1, stand 412, we will present the latest technologies and processes for robot-based automation of deburring and surface finishing processes.

Get your free trade show ticket – we are looking forward to your visit!

July 5, 2023

Automatica 2023 – Review

Four exciting and eventful trade fair days at automatica in Munich are behind ArtiMinds. We would like to thank all visitors for the great interest and the intensive personal exchange.

What were the highlights and which sensor-adaptive applications could be seen at our booth in hall B4? In our trade show review, we have compiled the most important information as well as a short trade show film.

June 23, 2023

Innovative robotics thanks to the use of laser scanners

For robotics, laser profile sensors, also known as laser scanners, open up new possibilities in factory automation and offer a reliable and cost-effective solution for precise 3D data acquisition. ArtiMinds RPS now also supports the use of laser scanners by integrating specialized predefined templates.

A good application example is the gripping and insertion of cables. With the ArtiMinds template library, the gripping point and the orientation of the gripper relative to the cable can be carried out quickly and reliably based on a scan of the cable end, allowing a wide range of feeding techniques to be implemented.

We have summarized all the important information about the laser scanner integration, advantages and alternatives in a compact leaflet.

June 14, 2023

Why no-code and low-code tools have become indispensable in robotics

With modern robot systems, almost all processes can be automated. Ususally, robots take over simple, dirty, monotonous or physically demanding tasks. However, with the right hardware and, above all, software, very complex and demanding tasks, so-called “Advanced Robotics” applications, can also be solved. The latest ArtiMinds article, published in the trade journal IEN Europe, reveals 3 tips for a time and cost-efficient implementation of robot-based automation processes in your manufacturing and why no-code and low-code tools have become indispensable in robotics.

May 30, 2023

What Makes No-Code and Low-Code Tools So Popular?

“To unlock the power of software development without coding” – That´s what no-code and low-code tools promise to do. Looking at robotics automation, our latest blog post highlights why these tools are revolutionizing the industry, empowering citizen developers, boosting collaboration, and accelerating innovation.

May 5, 2023

3 Questions to… Florian Aumann

Who are the people who are shaping robotics at ArtiMinds every day? The format “3 Questions to…” reveals more and introduces the faces and the team.

Today, Florian Aumann is answering our questions. Of course, how could it be otherwise: as a software developer, he enjoys searching for and finding solutions to complex, technical problems the most. And he has been doing this for six years now!

How does Florian describe himself in three words? As a cheerful nature, nerd and idealist.

1. What does a typical work week look like for you?

Most of the time I deal with RPS development. This can be both small and larger projects for customer-specific but also internal requests. Of course, regular meetings with customers or colleagues are a must. Often you can also find me in the Automation Engineering department, where I help dealing with questions and projects. On Fridays, a successful week is rounded off with a traditional Thai meal together with the team!

2. What do you do to balance your professional life?

My weekends with my girlfriend in Coburg in Bavaria are particularly relaxing. I also enjoy hiking and cooking.

3. What is your personal motto?

We´ll get it right!

April 26, 2023

New Whitepaper: Achieving Automation – but how?

Cost pressures, shortage of skilled workers, tense supply chains, aspired reshoring, or unattractive work tasks – there are plenty of reasons and drivers for automating processes.

But how do you identify the manufacturing processes and work tasks with the greatest automation potential in your production? What role does robot-based automation play and how are you able to avoid pitfalls?

Our new whitepaper provides helpful tips and shows you the path to automation as a step-by-step guide.

April 24, 2023

Don´t miss: ArtiMinds at automatica 2023

Automatica is the world’s leading trade fair for Smart Automation and Robotics and will be the industry’s meeting point from June 27 to 30.

Contact us to receive a free ticket to visit the exhibition and ArtiMinds in Hall B4, Booth 204.

We are looking forward to your visit and our personal exchange!

March 27, 2023

Release of ArtiMinds RPS 1.21

The latest ArtiMinds RPS version 1.21 is now available for installation. The update includes, among others, several enhancements and new features like the new tool “Meander” to create edges on a CAD surface, the new template “Point Inverse” for calculating the inverse pose of a point as well as a new wizard that guides through the calibration process for 3D models and/or points (3-Point Calibration Wizard).

You can find the entire change log with all changes and bug fixes in the ArtiMinds RPS directory.

The release is available via download or online update.

March 24, 2023

New Video Tutorial

ArtiMinds RPS generated robot programs are prepared to be easily maintained by service personnel. Even after local changes have been made, ArtiMinds offers options to synchronize the program on the robot with the digital representation in ArtiMinds RPS.

In this video, see how easy it is to teach waypoints or bases of robot programs generated by ArtiMinds. Later, the local changes are imported into the software again and the simulation is updated automatically.

March 16, 2023

Robotics Tip: Maintenance 2.0 – Teachpoint optimization

Until a robotic system is fully up and running in continuous operation, many steps have to be performed during planning, setup, commissioning and ramp-up. Those aspects are usually taken into account sufficiently, however, the effort of maintenance during runtime is most often underestimated. Component and machine tolerances, mechanical wear, human error, general environmental influences, and the setup of new variants can create a significant amount of work.

How you can reduce the effort during maintenance with ArtiMinds RPS and LAR software and at the same time increase the efficiency of the maintenance processes, we explain in our current Robotics Tip article.

March 3, 2023

3 Questions to… Jonas Langeheine

Who are the people who are shaping robotics at ArtiMinds every day? Our new format “3 Questions to…” reveals more and introduces the faces and the team.

Let’s start with our Product Manager Jonas Langeheine, who is responsible for a customer- and application-centric product development.

He tells us what his day-to-day work is like, what he particularly enjoys about his job and how he likes to spend his free time.

February 2, 2023

Don´t miss: ArtiMinds at all about automation trade show in Friedrichshafen

At all about automation you will experience systems, components, software and engineering for industrial automation and industrial communication.

Get your free ticket and visit us at our booth B2-305

February 1, 2023

Release of ArtiMinds RPS 1.20

The latest ArtiMinds RPS version 1.20 is now available for installation. The update includes, among others, extended integrations and functionalities for UR, KUKA and FANUC as well as new builders and templates to read and write the coordinates of a point.

You can find the entire change log with all changes and bug fixes in the ArtiMinds RPS directory.

The release is available via download or online update.

January 17, 2023

NEW: Robotics Glossary

What does online or offline programming mean, or what is an Euler angle or force-torque sensor, and what is meant by continuous path control?

We have collected these and numerous other technical terms from the fields of robotics, industry and artificial intelligence as well as ArtiMinds specific terms and explained them in our robotics glossary.

January 10, 2023

Robotics project consulting and engineering services from ArtiMinds

According to your individual requirements, our experienced Automation Engineering team can support you with consulting services in all phases of your project.

From developing the automation idea, to concept development, to prototypical implementation of the robot application as a feasibility study – our Automation Engineering team has many years of experience in robot-based automation and sensor-adaptive robotics.

Until the final transfer of the results to the shop floor, e.g. together with your machine builder or system integrator, we are the right partner for your robot-based automation project!

December 16, 2022

Best Practice: Robotic grinding application for processing weld seams

In cooperation with ArtiMinds the company SHL successfully automated a highly challenging weld finishing robot application. The goal was to develop a flexible solution without any pneumatic spindles, since those are hard to monitor and cumbersome to maintain.

The work pieces, which vary in size and dimensions, consist of several pipes welded together. The task was to remove the excess material at the weld seam on the inside of the work pieces.

Programming such force-sensitive tasks typically requires a high level of robotics and programming expertise. However, with the software solutions and programming support from ArtiMinds, SHL set up, commissioned, and identified the optimal process parameters in just a few days.

Learn more about the project and cooperation in the corresponding application video.

December 7, 2022

Explainer Video: ArtiMinds LAR

ArtiMinds LAR is the central solution for analyzing robot process data for holistic monitoring and optimization of automation processes.

The tool analyzes live sensor data of the robot, such as occurring forces, tool paths and velocities and automatically combines them with process information such as part serial numbers, process steps and sequence information.

Watch our latest video to learn how ArtiMinds LAR can support you in optimizing production processes and how the data is helpful for various stakeholders in your organization.

October 21, 2022

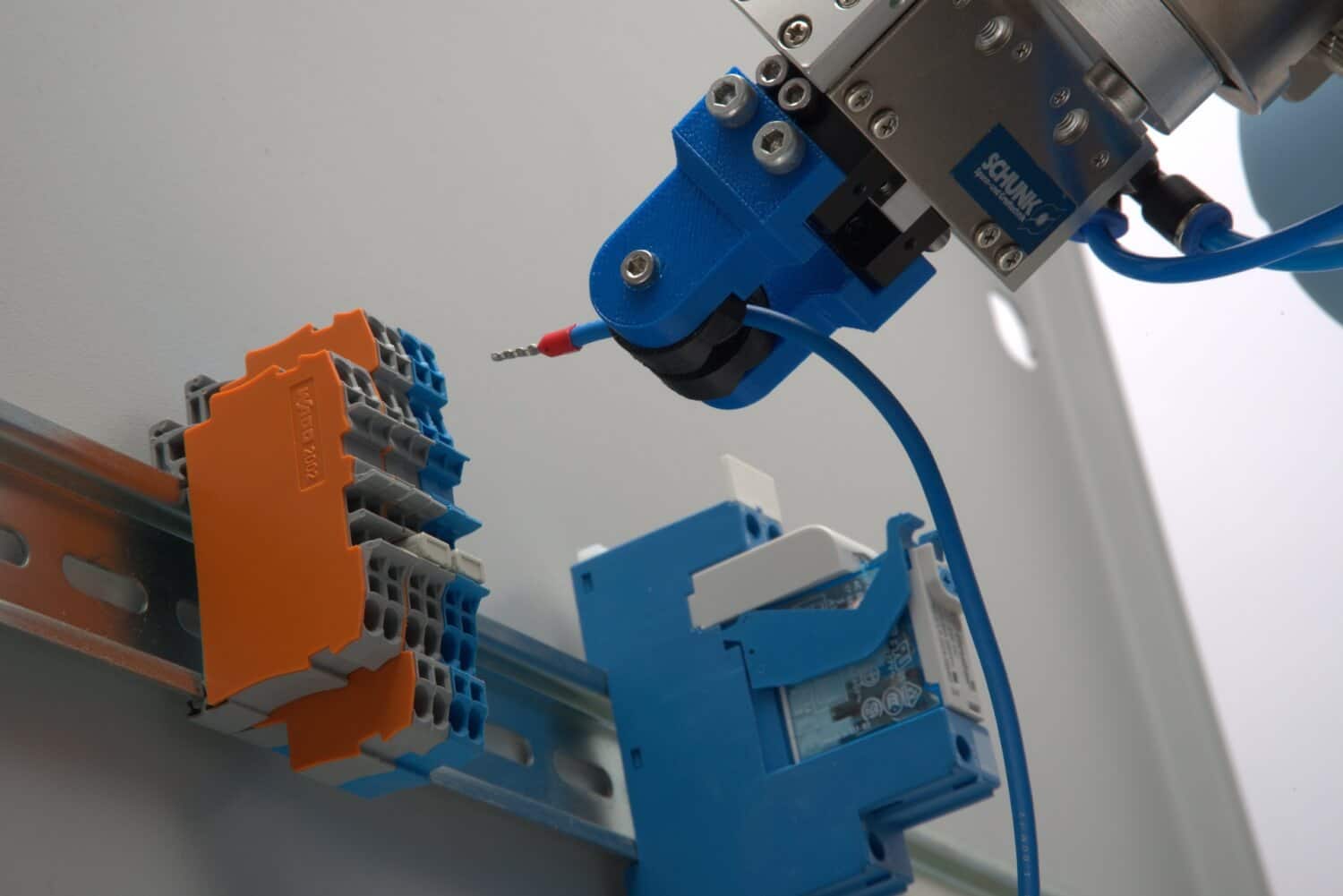

Cable assembly and handling

Automated handling, manipulation, and assembly of flexible workpieces such as cables, tubes, or fabrics/fabric cover pose several challenges in production. Traditional robot processes often lack the dexterity to handle these sensitive materials. Localization of the position and identification of the shape of parts are a major challenge in classic robot programming. The liability and form instability of the material results in constantly changing dynamic of the part tolerances, shape, and localization throughout the entire assembly process.

But robot-based cable assembly can now be programmed and implemented with ArtiMinds RPS.

September 1, 2022

Successful AI research in Baden-Württemberg

As a research-strong and innovative state, AI is a key technology for Baden-Württemberg. Three examples from research and applied research, showcased in a short movie by Baden-Württemberg International, highlight the state’s potential, success and diversity of ideas in the field of AI.

ArtiMinds is presented as one of the three examples. „In Baden-Württemberg there’s this spirit of making things actually work and not shiny“, Dr.-Ing. Darko Katic, Senior Teamleader AI at ArtiMinds Robotics, sums up the LÄND’s great potential in AI.

August 19, 2022

These applications can be realized using ArtiMinds

To know how: ArtiMinds is not just template-based programming software for industrial robots. With ArtiMinds, sensor-adaptive processes in particular can be programmed much more easily and industrialized more quickly.

Why? Because the more than 60 function templates contain intelligent algorithms that ensure that the robot executes, for example, a plugging process as quickly and precisely as possible and even optimizes itself over several cycles.

Our new video shows which applications can be realized using ArtiMinds RPS and LAR:

May 6, 2022

Free Robotics Checklist

Are you planning a robotics project? To ensure efficient planning and integration, it is important to think about the concept and requirements of the application, your goals, the technical prerequisites and the requirements for human-robot collaboration in advance.

Use our interactive checklist and the supplementary tips to make sure you don’t forget any important points and to find the right hardware components and software tools for your application.

April 12, 2022

Easy Robot Program Transfer Without Loss of Process Parameters

A robot programming developed with ArtiMinds RPS can be easily transferred to robots of other manufacturers.

As the software uses a generic template program to create native robot code, force-controlled assembly processes etc. can be transferred easily while maintaining the parameters of the process. Reteaching due to kinematic changes is fast and easy.

So, for example, a feasibility study can also be realized with a Cobot. Later, an industrial robot can be used for the robotic cell.

March 11, 2022

Bin Picking and Force-Controlled Assembly

Unsorted components can be robustly detected with the Keyence Bin Picking System RB-800, while the search algorithms of ArtiMinds RPS take over the downstream force-controlled assembly of the components – an ideal combination.

February 16, 2022

Robotics Best Practice: How Maus automated the grinding process of aluminum mold shells

The grinding of molded shells is a physically demanding job, but due to the complex geometries the task cannot actually be automated with robots. With the support of ArtiMinds, however, Maus GmbH has now found a solution that allows the robot to grind out the shells in a force-controlled and precise manner.

Melchior Maus, master degree in technical model making, reports: “Up to now, we had no experience with robots. But with their software solution and expertise ArtiMinds opened the door into the field of robotics for us. Our vision is that every workstation in mold construction will have a robot to assist the worker in grinding out the molded shells.”

In the latest Success Story video, Melchior Maus explains the details of the application and tells what benefits he has had by using ArtiMinds RPS and cooperating with ArtiMinds.

February 11, 2022

Why operational effects are very time consuming for robot programmers

During the lifecycle of a robotic cell, a system is exposed to numerous operational influences.

These can be shocks and vibrations triggered, for example, by forklifts or other machines, the wear of tools, spare parts that react differently than the previous components, changes in work piece batches or space available in the hall. Changing lighting and temperature conditions or the difference between a cold-started and a warmed-up robot can also have an effect.

What does this mean in concrete terms? Our latest blog reveals the facts!

January 12, 2022

Gripping, greasing, joining – force-controlled gear assembly with ArtiMinds

Primus Präzisionstechnik manufactures and supplies customized motor-gear units, which are developed individually. Being innovative is one of the most important criteria to stay one step ahead of the competition. In order to increase product quality and process stability, and to reduce costs through better dosing of grease when greasing gears and shafts, Primus automated the assembly process of a gear unit for the automotive sector using robots.

Although the team had no experience in robotics prior to this project, using ArtiMinds RPS robot programming software and LAR analysis software Primus was able to program the application independently and to implement a flexible robot cell.

Quality was increased as desired and the reject rate was reduced to almost zero.

More about the cooperation and application in the Case Story Video!