Surface processing with robots

Polishing – Grinding – Gluing – Deburring – Painting with ArtiMinds RPS

The software ArtiMinds RPS, combines offline and online programming in a unique way to solve applications requiring precise tool paths. Easily create tool paths based on the CAD geometry of your parts or import a tool path directly from your CAD file. Quickly check for collisions and reachability to figure out the best layout of your robot cell. Connect to the real robot to calibrate the robot program, teach key poses and optimize parameters.

The challenges of robot-based surface processing, such as deburring, polishing or grinding, lie in the compensation of tolerances, the programming of sensor-adaptive processes and the handling of complex geometries. Furthermore the integration of force-torque sensors, camera systems or special tools and the interaction with the robot requires special programming skills.

The innovative functionalities of the ArtiMinds RPS enable the most diverse forms of surface processing. For example, thanks to the easy import of CAD files, robot motion paths can be simulated and created automatically.

You need support in automating an electronics assembly process? At ArtiMinds you get software & project support from a single source!

You would like to implement a robotics project? Use our free robotics checklist to select the right hardware & software and to organize the most important project steps!

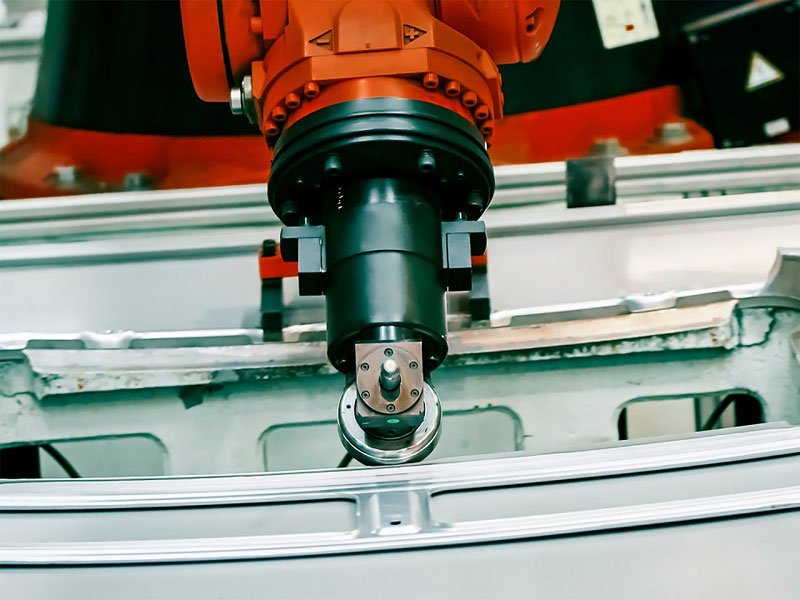

Application example: Deburring

The removal of burrs is a common step in the post processing of metal and plastic injection moulded parts. Since these can have complex geometries, path planning for deburring is difficult to implement. For this purpose the CAD2Path tool of the ArtiMinds RPS can be used. The CAD2path tool allows to import CAD model geometries into the RPS and to generate paths along a contour. In addition, the orientation of the TCP to the imported path is adjustable which is important for deburring operations.

Thanks to the large number of supported robots and peripheral devices as well as seamless online and offline programming, the ArtiMinds RPS software offers optimal support for robot-based surface processing tasks. Whether you need to to solve tasks like grinding with constant contact pressure, polishing detected defects, full-surface polishing or deburring of components with complex geometries – ArtiMinds RPS delivers the right robust robotic program for all challenges.

.

Further application examples:

- Polishing and buffing of surfaces

- Grinding and deburring of edges and corners

- Glue bead dispensing

- Painting

You want more? We support you in the robot-based automation of your surface processing

You want more? We support you in the robot-based automation of your surface processing

You want to integrate new and flexible automation processes into your workflows and need e.g. support in the deburring or polishing of workpieces? Our Automation Engineering team of engineers and robotics experts will be happy to advise you and take over tasks such as the prototyping.

ArtiMinds is a leader in the development of innovative and sophisticated robot automation solutions, whether as a partial or overall concept. Our experts will be happy to provide you with advice and support from conceptual design to implementation.

Get in touch – our specialists will provide you with comprehensive advice and develop an initial concept or carry out a feasibility study in close cooperation with you.

Industrial examples – short videos of real customer applications

ARTIMINDS – YOUR HOLISTIC ROBOTICS PARTNER FOR SURFACE PROCESSING

OUR OFFERING:

Link to: Robot Programming Software

ROBOTICS SOFTWARE

Link to: Consulting & Engineering

ROBOTICS ENGINEERING

Why ArtiMinds Robotics?

With its sensor-adaptive and intelligent program templates, ArtiMinds RPS meets the diverse requirements of surface processing. Due to the hardware independence and the simple integration of force-torque and vision sensors, you benefit twice: You have a robust automation solution and yet remain flexible in your hardware setup and application.

>>READ THIS BLOG POST: Setting up automated grinding applications faster

Highlights of ArtiMinds RPS for surface processing:

- Easy tool path generation from CAD

- Force-controlled, sensor-adaptive movements

- Collision checks and reachability tests

As a leading solution and software provider for demanding robot applications, ArtiMinds Robotics supports you in all phases of your automation project: from planning & programming, commissioning and operation up to analysis and optimization. We would be happy to show you the possibilities in a short online demo!

>>THAT´S WHAT OUR CUSTOMERS SAY<<

With ArtiMinds RPS, automation solutions are possible where classic robot programming reaches its limits. Read the detailed report on how Visomax Coating GmbH was able to develop new robot applications for force-controlled surface processing with the help of ArtiMinds RPS.

Just get in touch. Our application experts will be happy to advise you on your individual automated robot application. Make an appointment right now for an online demo and learn how ArtiMinds can help you to implement a flexible robotic automation project.

Browse through our Robotics Blog or FAQ section and learn interesting facts about ArtiMinds RPS & LAR. Our Download & Press area provides further information. Or sign up to our newsletter for regular news and ongoing updates.

FREE ONLINE DEMO: GET STARTED AND LEARN MORE ABOUT ROBOT-BASED AUTOMATION

In just a few minutes, we will show you how to plan, program, operate, analyze and optimize robot applications cost-efficiently, intuitively and easily with ArtiMinds RPS.

The non-binding free online demo is the perfect way to get a first impression of the software, the application portfolio and if it suits your needs.