Plan

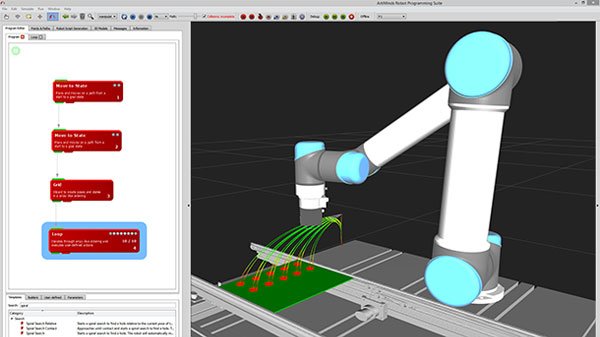

Plan and simulate your robot-based automation solution with ArtiMinds RPS. Realize your applications with a minimal amount of expensive special-purpose hardware. Easily set up your robot using a broad set of standard components like grippers, force-torque sensors and vision sensors. Import CAD files to quickly check reachability and collisions of the robot. Choose the best hardware suitable for your process and optimize the layout of the robot cell using the reachability assistant. Easily generate paths from CAD to validate the robot motions as early as possible – for specific tasks like dispensing, cutting or deburring.