KUKA Roboter effizient programmieren und teachen

ArtiMinds – Die Software für KUKA.WorkVisual kompatible Roboterprogramme

Die standardmäßige Programmierung von KUKA Robotern erfolgt durch Schreiben von KUKA Robot Language (KRL) Code in der Systemsoftware KUKA.WorkVisual oder KUKA Sunrise.OS. KUKA.Sim unterstützt speziell bei der Simulation von KRL Programmen und der Offline-Programmierung.

Wenn es um das Programmieren und Teachen von KUKA Robotern geht, ist die Software ArtiMinds RPS eine echte Alternative, da alle Funktionen in einer Software zur Verfügung stehen und kein Skriptcode geschrieben werden muss. Selbst anspruchsvolle Roboteranwendungen lassen sich einfach mit ArtiMinds programmieren, ohne eine einzige Zeile KUKA Programmcode selbst schreiben zu müssen.

KUKA bietet derzeit rund 25 Industrieroboter in zahlreichen Varianten mit verschiedensten Traglasten und Reichweiten an. Daher eignen sich KUKA Roboter für nahezu alle Anwendungen. In den Bereichen Handling, Montage, Palettieren und Verpacken sind die Industrieroboter von KUKA besonders stark.

Die zahlreichen Einsatzmöglichkeiten und Features machen die Programmierung jedoch schnell auch komplex und Anwendern fehlen häufig die Programmierkenntnisse, um alle Funktionen voll ausschöpfen und für Ihre Anwendung einsetzen zu können.

ArtiMinds RPS unterstützt alle KUKA 6-Achs-Roboter mit KR C4 und KR C5 (mit KSS 8.7) Steuerung.

KUKA Roboter Programmierung in der Praxis

Warum KUKA Roboter mit ArtiMinds programmieren?

Sie möchten mit Ihrem KUKA Roboter anspruchsvolle Aufgaben lösen, ohne tagelangen Aufwand in die Programmierung stecken zu müssen? Sie haben vor, in die robotergestützte Automatisierung einzusteigen und möchten gerne einen KUKA Roboter einsetzen? Sie möchten mit Blick auf die Zukunft herstellerunabhängig bleiben und in der Lage sein, Anwendungen auch ohne Neuprogrammierung auf andere Roboter übertragen zu können?

Mit der Software ArtiMinds RPS sind Sie und Ihre Mitarbeiter in der Lage, ohne langwierige und teure KUKA Schulungen jegliche Art von Anwendung zu realisieren und Ihren Roboter selbst zu programmieren und zu teachen. Dank der über 60 vordefinierten Programmbausteine sorgt ArtiMinds für robuste industrielle Anwendungen und eine schnellere Programmierung. D.h. für Sie, weniger Kosten, mehr Effizienz und neue Einsatzmöglichkeiten.

ArtiMinds & KUKA – Take Aways

- Nativer wiederverwendbarer KRL Code wird automatisch erstellt

- Den vollen Funktionsumfang des KUKA Roboters ohne spezielle Programmierkenntnisse nutzen

- ArtiMinds RPS als Alternative zu KUKA.WorkVisual, KUKA.Sim oder diverser Applikationssoftware von KUKA

- Eine Softwarelösung für Online- und Offline-Programmierung, Simulation und Optimierung

Entscheiden Sie sich für eine robuste, flexible und erschwingliche Automatisierungslösung – entscheiden Sie sich für ArtiMinds.

Gerne zeigen wir Ihnen in einer Online-Demo, wie Sie KUKA Roboter mit ArtiMinds programmieren können und welche Anwendungen möglich sind.

Wie unterstützt ArtiMinds die Effizienz Ihres KUKA Roboters?

Um auch das letzte aus Ihrem KUKA Roboter herauszuholen, gibt es bei ArtiMinds zwei Ansätze – die ArtiMinds Robot Programming Suite (RPS) und ArtiMinds Learning & Analytics for Robots (LAR).

ArtiMinds Robot Programming Suite (RPS) kombiniert als Roboter Programmier-Software sowohl Online- als auch Offline-Programmierung auf intuitive Weise, um anspruchsvolle Roboteraufgaben Ihres KUKA Roboters zu lösen, ohne eine einzige Zeile KRL Quellcode zu schreiben. Integrieren Sie Endeffektoren, Kraftsensoren, Bildverarbeitungssysteme und SPS-Kommunikation, um flexible Automatisierungslösungen zu erstellen.

Der automatisch generierte Robotercode läuft direkt auf der KUKA KR C4 oder KR C5 Robotersteuerung – ArtiMinds RPS benötigt keine zusätzliche Hardware.

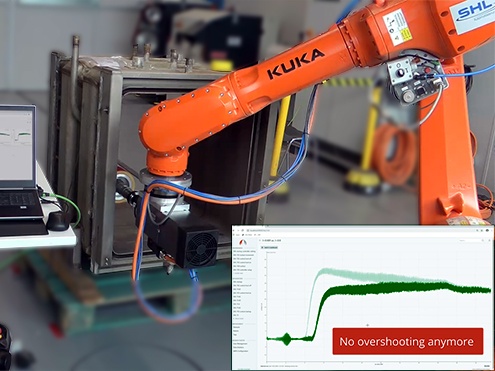

Mit ArtiMinds Learning & Analytics for Robots (LAR) erhalten Sie detaillierte Einblicke in die Produktionsprozesse Ihres KUKA Roboters. Basierend auf ArtiMinds RPS werden Live-Sensordaten von Roboter, Kraftsensor, Bildverarbeitungssystem und Endeffektor automatisch von der KR C4 und KR C5 Robotersteuerung übertragen. Die Sensordaten werden automatisch annotiert und dauerhaft in Ihrer internen Datenbank gespeichert. Analysieren Sie diese Sensordaten anhand verschiedener KPIs und grafischen Auswertungen. So überwachen Sie die Produktion, analysieren die Roboterbewegungen und optimieren Ihre KUKA-Programme.

Worin wir KUKA Roboter effizienter machen können

Mit ArtiMinds RPS und LAR erleichtern wir die Entwicklung und den Betrieb von flexiblen Automatisierungslösungen u.a. mit KUKA Robotern in nahezu allen Branchen. Nachfolgend finden Sie einige Anwendungsbeispiele für die Programmierung von KUKA Robotern mit ArtiMinds RPS. Unsere Lösungen helfen aber auch bei Prozessen in anderen Bereichen.

JETZT UNVERBINDLICH ONLINE-DEMO TERMIN ANFRAGEN

In nur 30 Minuten zeigen wir Ihnen, wie Sie mit ArtiMinds RPS Ihre Roboterapplikationen kosteneffizient, intuitiv und einfach programmieren können.

Die unverbindliche Online Demo ist die perfekte Möglichkeit, sich einen ersten Eindruck von der Software und den Anwendungsmöglichkeiten zu verschaffen.