Automation solutions and applications

Classical and new fields of application for industrial robots

The fields of application for industrial robots are numerous and versatile. They range from high-performance handling to plugging cables, from palletizing to force-controlled surface processing, and many more. They can be found both in classic large-scale production and in numerous new fields of application for automated robot applications. However, new challenges such as fluctuating production batch sizes, high variances, shorter production cycles and a shortage of skilled workers must also be managed. In order to remain competitive and to be able to guarantee highest efficiency and cost-effectiveness, a flexible production environment is required.

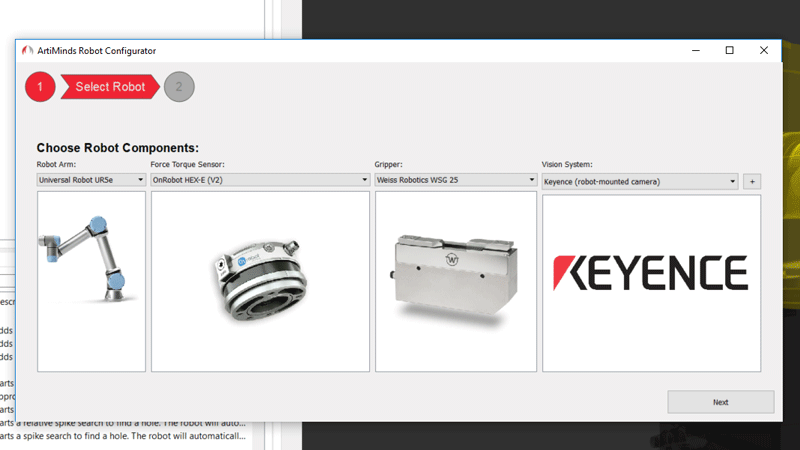

According to the different requirements, industrial robots and peripherals such as force-torque sensors, electric grippers and image processing systems like vision sensors from different manufacturers can be found in a manufacturing facility. The process from planning to programming up to commissioning of a robot application is frequently very time-consuming and thus also cost-intensive. Furthermore experts are needed to program the robot in the specific manufacturer’s language and to manage ongoing optimizations.

ArtiMinds RPS and LAR facilitate the development and operation of flexible automation solutions with robots in almost all industries. Typical applications include electronic manufacturing, mechanical assembly, cable & wire harness assembly, bin picking, quality assurance, handling and packaging, as well as laboratory processes.

Free Robotics White Paper

“THIS IS HOW AUTOMATION WORKS”

Robotics for your Company: :

Opportunities – Obstacles & Stumbling Blocks – Solutions

In our free white paper, we show which stumbling blocks you should watch out for when implementing robotics applications, how you can avoid them, and give a broad overview of typical robot applications and use cases.

Robot-based automation – that´s what it should look like

- Flexible and agile during deployment and operation.

Example: being able to make changes to the hardware setup and to adapt the robot program without special robotics expertise. - Robust in programming.

Example: compensation of variances and product tolerances and prevention of interface problems. - Cost-effective.

Example: Your employees are able to independently program robot processes – and remaining independent in the hardware selection at the same time.

These and many other features are offered by the ArtiMinds Robotics software products RPS and LAR!

ArtiMinds RPS and LAR offer solutions that were previously not feasible

ArtiMinds is your partner to flexibly automate your production processes and thus, offers companies of all sizes software solutions and services for the programming and operation of robot applications. From “simple” to “highly complex and demanding” tasks, we are the right contact for you. The following customer example shows how ArtiMinds RPS and LAR make solutions possible, which have been impossible so far:

„Airbags are sewn together in a ZF plant in Portugal. The challenge is to keep the sewing speed constant, even if the airbag does not have a uniform geometry.” Realizing this task with a robot proved to be unexpectedly difficult. Because, according to Arnold, “The robot sits almost centrally from the component. This means that depending on how far and at what angle the robot arm has to move, the speed of movement would have to be adjusted continuously.”

The colleagues from Portugal had tried for several weeks to solve this task and finally gave up. Even with external system integrators, the requirements did not seem to be feasible. Together with the ArtiMinds project team, ZF was finally able to work out a good solution for the implementation of the robot program.

Extract from an ArtiMinds success story with the customer ZF Friedrichshafen. Find out the whole story.

What do you want to automate?

Are you looking for a robust, flexible and affordable automation solution? ArtiMinds technology powers not only classical high-volume applications but also new applications with high-mix low-volume (HMLV). The unique features of ArtiMinds RPS and LAR make solutions possible, which have been impossible so far.

Talk to our experts about your specific needs, we will be pleased to support you! Please feel free to contact us regarding your specific application via the contact form.

ArtiMinds for your robotic automation project

ArtiMinds for your robotic automation project

You want to integrate new and flexible automation processes into your workflows?

ArtiMinds is a leader in the development of innovative and sophisticated robot automation solutions, whether as a partial or overall concept. Our experts will be happy to provide you with advice and support from conceptual design to implementation. Get in touch – our specialists will provide you with comprehensive advice and work with you to develop an initial concept or feasibility study.

Write to us and start your automation project with ArtiMinds.

GET STARTED AND LEARN MORE IN A FREE ONLINE DEMO

In just a few minutes, we will show you how to plan, program, operate, analyze and optimize robot applications cost-efficiently, intuitively and easily with ArtiMinds RPS.

The non-binding free online demo is the perfect way to get a first impression of the software, the application portfolio and if it suits your needs.