ROBOT-BASED ASSEMBLY OF STRETCHERS – programmed with ARTIMINDS RPS

Siemens Healthineers

Another software foundation for the site in Kemnath

THE CHALLENGE

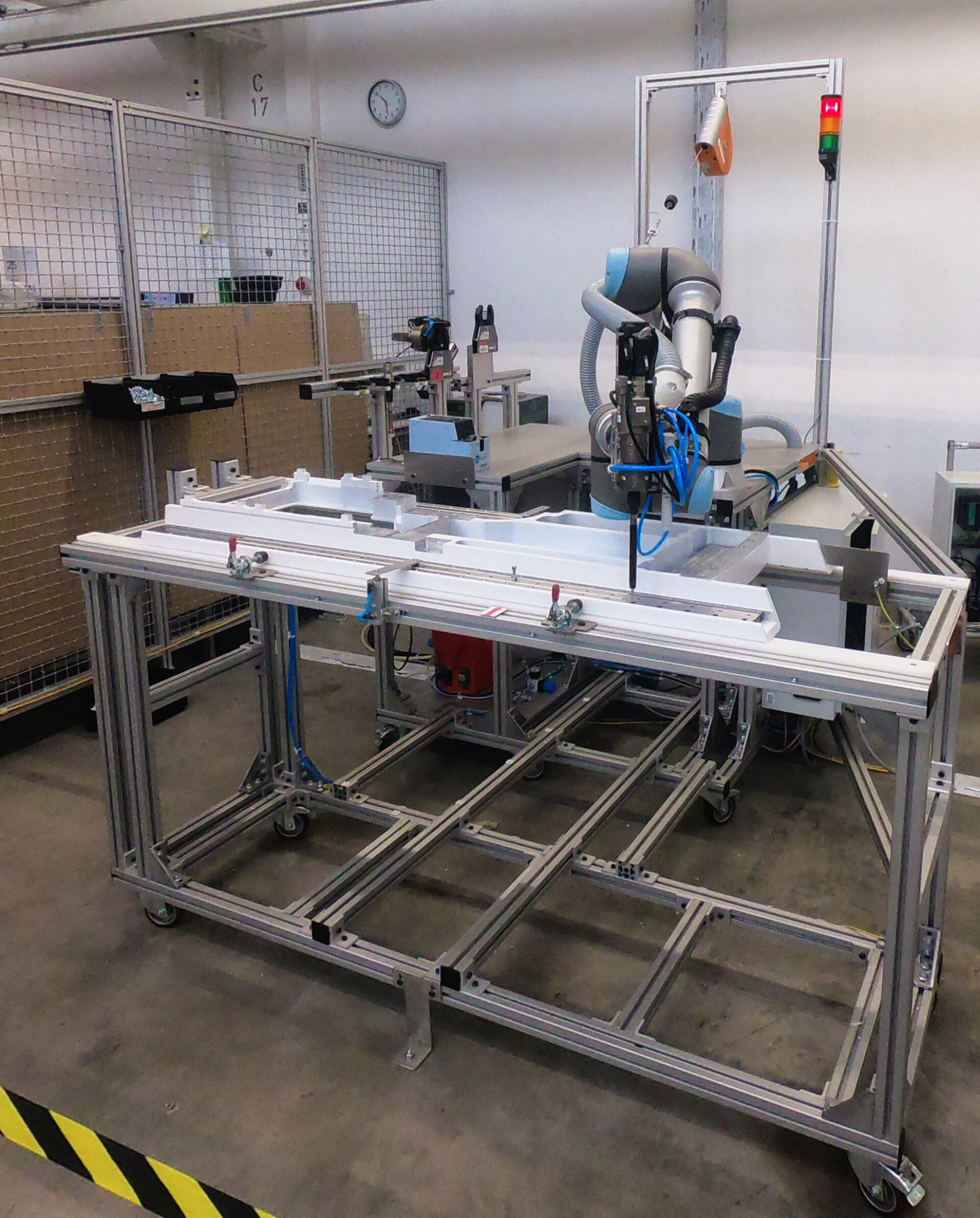

Siemens Kemnath produces stretchers, among other things. Stretchers are used to insert patients into the imaging systems of the Siemens Healthineers products. For this, the stretchers are moved horizontally on a linear axis. Until now, the assembly of those axes was mostly done in a manual process which included 280 screws to be set per stretcher in total. “The work was partly done overhead or while bent over, because the screws have to be fed from below as well as from above”, states Florian Beer, Project Manager for Robotics and Automation. The component is often rotated and turned during assembly. “The work situation for our employees was very uncomfortable, but a robot does not really care about that”, tells Beer with a wink. The robot not only relieves the employees, but it also ensures process reliability: the robot reproduces the process 100 percent identically every time.

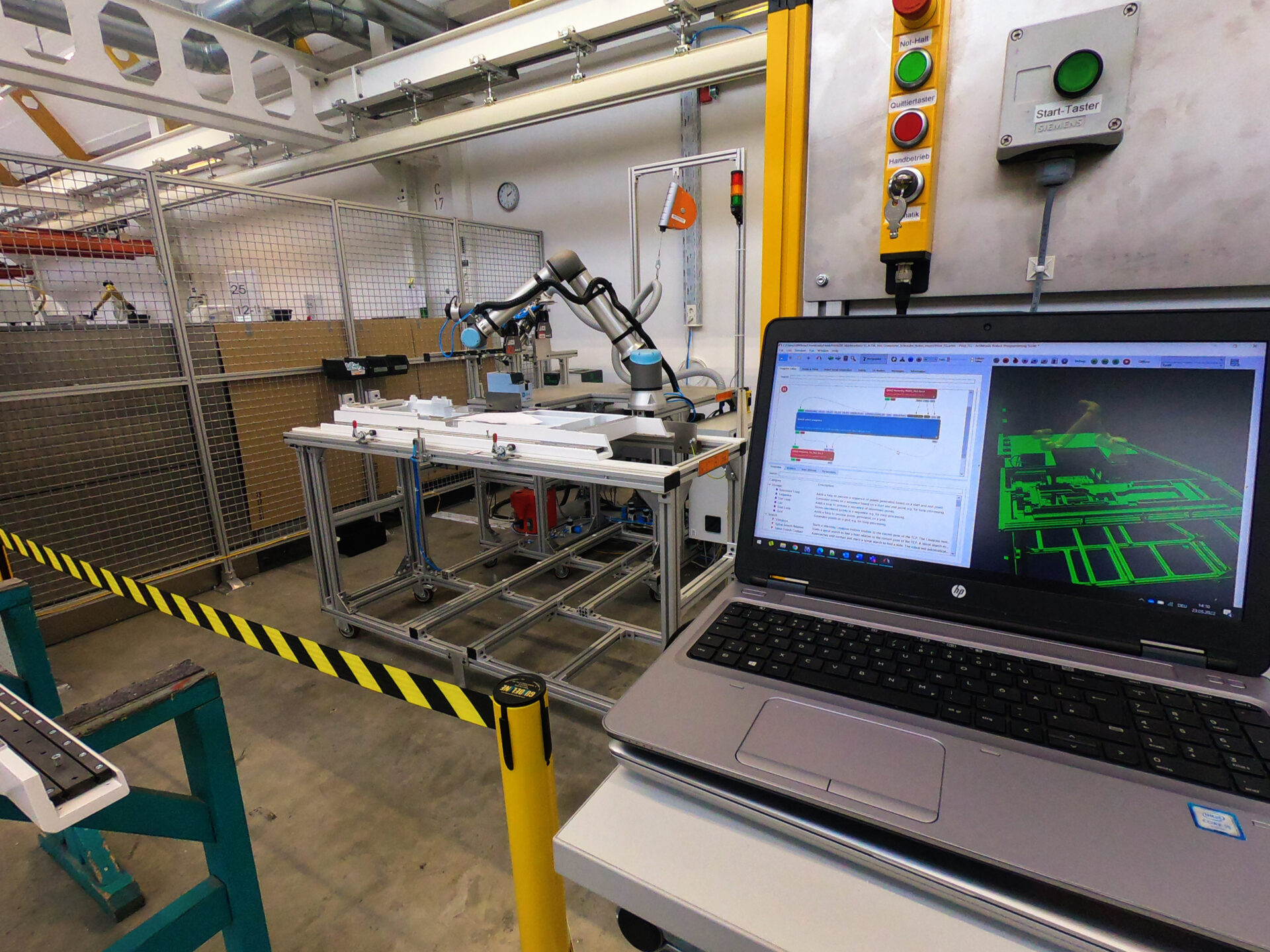

A robotic cell equipped with a lightweight robot and a special screwdriving system handles the manufacturing process. “The solution works so far, but is still strongly limited in some areas”, criticizes the project manager. “We have issues with the data transfer for example, especially with the communication between robot and screwdriving system, since the robot used acts as master but does not speak PROFINET.” A deficit that could only be solved via digital I/Os. This makes the structure inflexible. Changing the used robot manufacturer would come with a considerable amount of additional expenses.

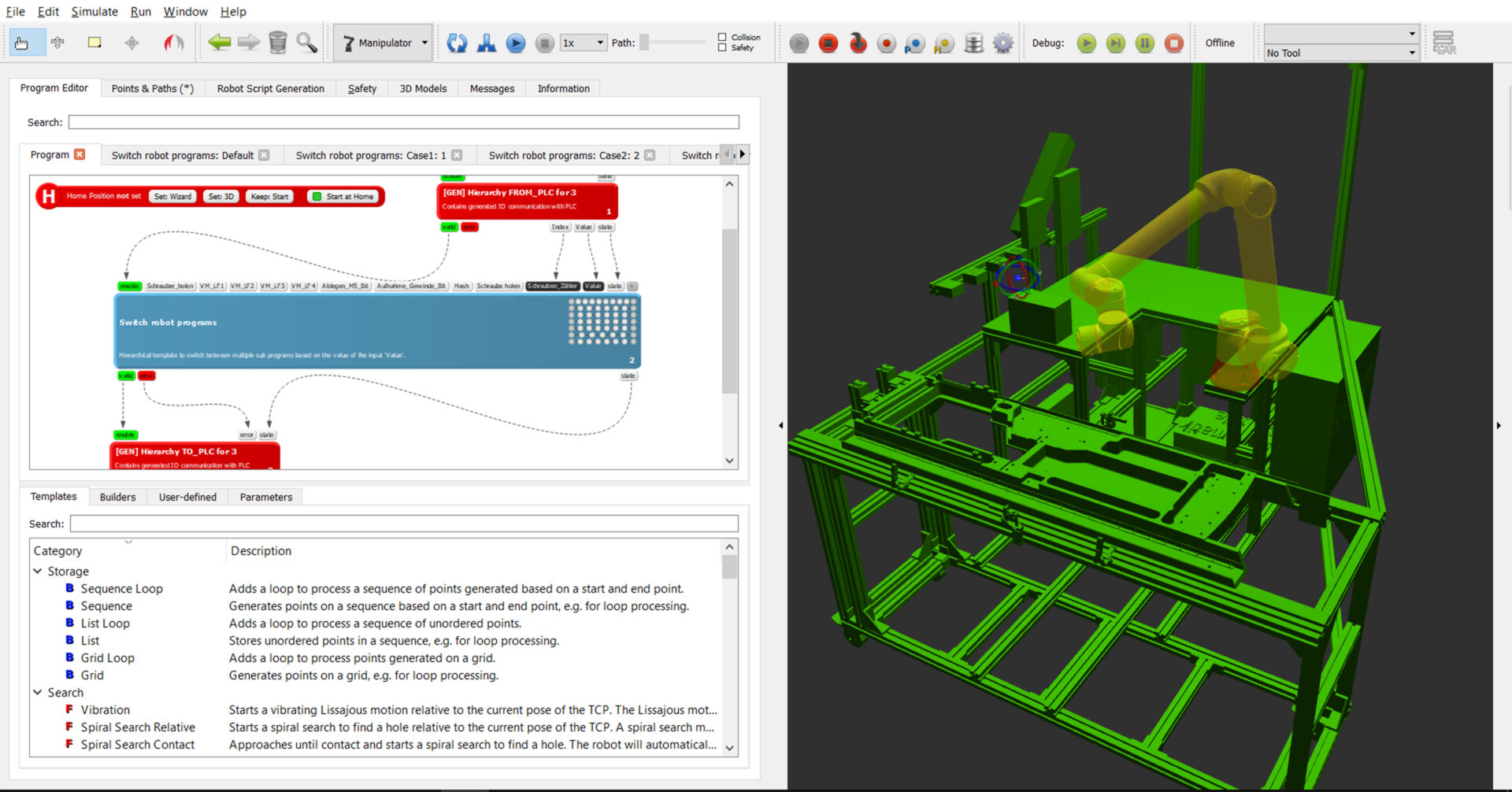

In addition, there is a lack of granularity in the programming of the individual machines: The lack of intermediate steps and subprograms makes it difficult to clearly structure the overall process. There are cases of emergency where the production has to be interrupted. If that happens, the possibilities to continue the manufacturing process at the correct processing step or to jump to the correct position in the program are very limited. Therefore it is planned to implement a master PLC into the current process.

THE SOLUTION

WHY ARTIMINDS?

“ArtiMinds RPS structures individual program steps granularly, which makes individual assembly processes easier to understand and the search for errors much simpler.”

Florian Beer, Project Manager for Robotic and Automation at Siemens Healthineers

THE ADVANTAGES

User-friendly handling

Beer is highly satisfied with the choice: “ArtiMinds RPS speaks with almost any robot. So even if the manufacturers vary, we do not have to start from zero and learn the programming respectively the programming languages again.” The software also automatically structures the generated robot program congruently to the process steps. If necessary, the granularity can then be further increased so that individual assembly processes are more comprehensible and the search for errors becomes much easier.

A big plus for Beer is the user-friendly handling of the software: “ArtiMinds RPS is very intuitively designed. With a two-day training and a little familiarization, using RPS anyone can program a robot within a few days. Programming knowledge is not required.” As robotics experts are rare on the market, this advantage makes the software so attractive to Beer. The department also regularly works with students who initially lack the appropriate robotics expertise. This means that junior colleagues can also quickly program and optimize robot cells using drag-and-drop, and long training periods are a thing of the past.

The pilot phase started in July 2021. Only eight months passed from conception to implementation to testing. Beer´s initial intermediate conclusion: “We see a clear additional value in the programming of our equipment. That is why we decided to take the pilot project from ‘proof of concept’ to serial production.”

In addition to the product itself, Florian Beer is also impressed by the support he receives from ArtiMinds. “In every pilot project, problems arise that were not anticipated. Then we simply made a quick call and worked together to find a solution. The cooperation was excellent”, he finally summarizes.

“ArtiMinds RPS is designed to be very intuitive. With the two-day training and a little familiarization, anyone can program a robot within a few days. Programming knowledge is not required.”

Florian Beer, Project Manager for Robotic and Automation at Siemens Healthineers

Take Aways of Siemens Healthineers when using ArtiMinds RPS:

- The graphical, intuitive user interface and pre-programmed function templates make it possible to solve complex automation tasks even with little or no programming knowledge.

- Fast and easy programming of PLC-controlled assembly processes.

- ArtiMinds Robot Programming Suite and the ArTIA Connector provide a coupling of robot and PLC.

- Unergonomic work that has to be done overhead or bent over is now carried out by a robot.

GET STARTED AND LEARN MORE IN A FREE ONLINE DEMO

In just a few minutes, we will show you how to plan, program, operate, analyze and optimize robot applications cost-efficiently, intuitively and easily with ArtiMinds RPS.

The non-binding free online demo is the perfect way to get a first impression of the software, the application portfolio and if it suits your needs.

With this white paper, we want to provide you with guidance for your automation plans. To help you to avoid typical pitfalls when using robots, we highlight the top 5 underestimated challenges and stumbling blocks when getting started in robotics and provide you with helpful tips and interactive checklists.

Link to: Primus Präzisionstechnik

In order to maintain high repeatability and process stability even for large quantities, Primus Präzisionstechnik automated the assembly of a gear unit using a flexible robot cell. The vision- and force-controlled application was programmed with ArtiMinds RPS.

MUCH MORE THAN JUST SIMPLE ROBOT PROGRAMMING: With RPS you create cross-process standardization – from planning and programming to maintenance.