You would like to integrate new and flexible automation processes into your workflows, but do not have enough resources in-house or have not yet built up the corresponding expertise?

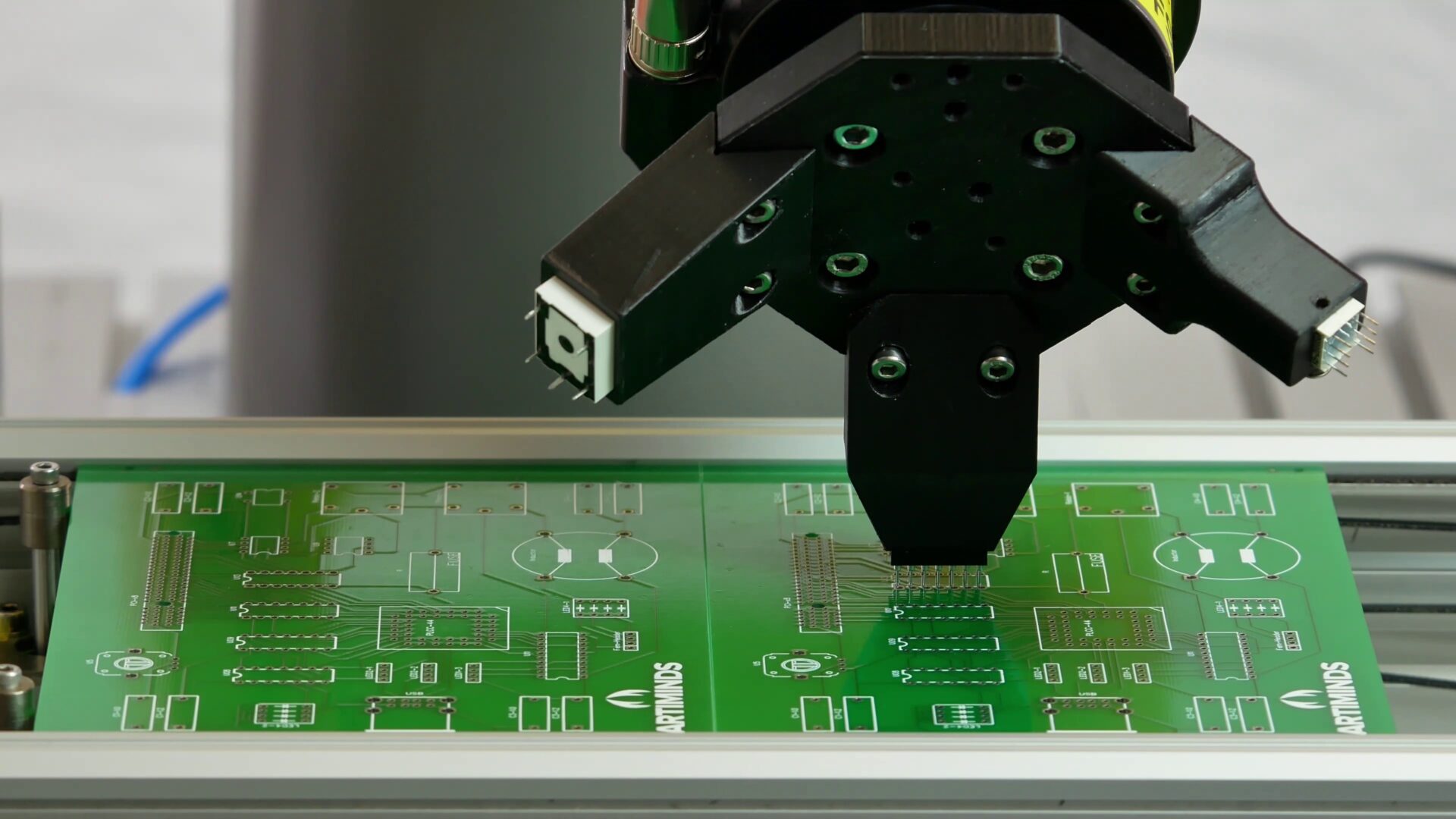

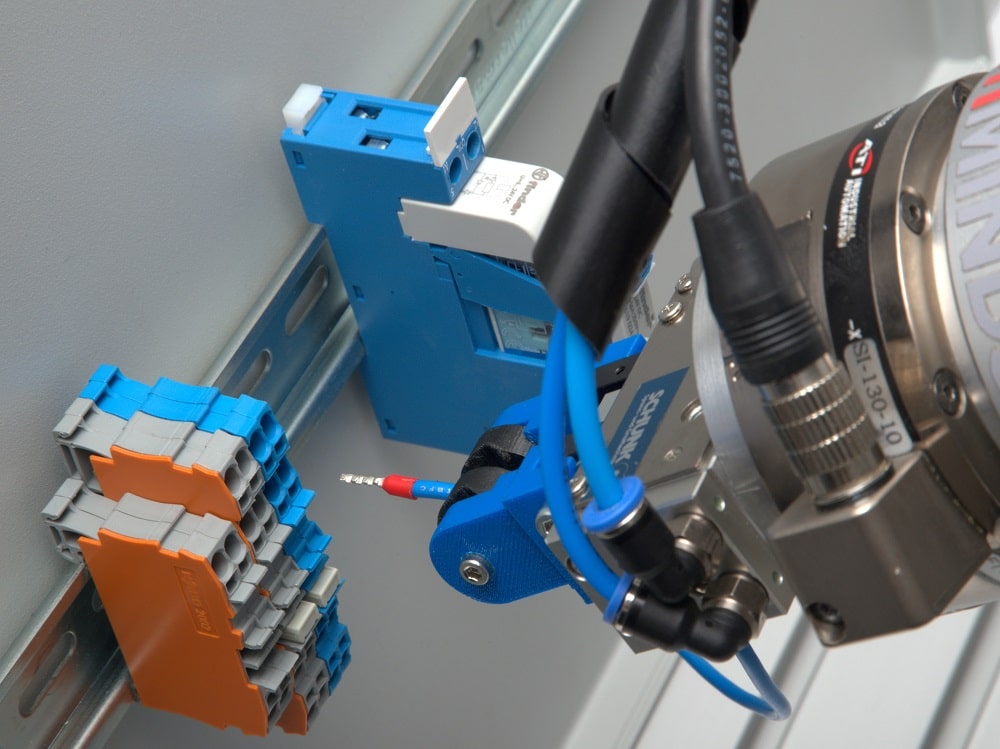

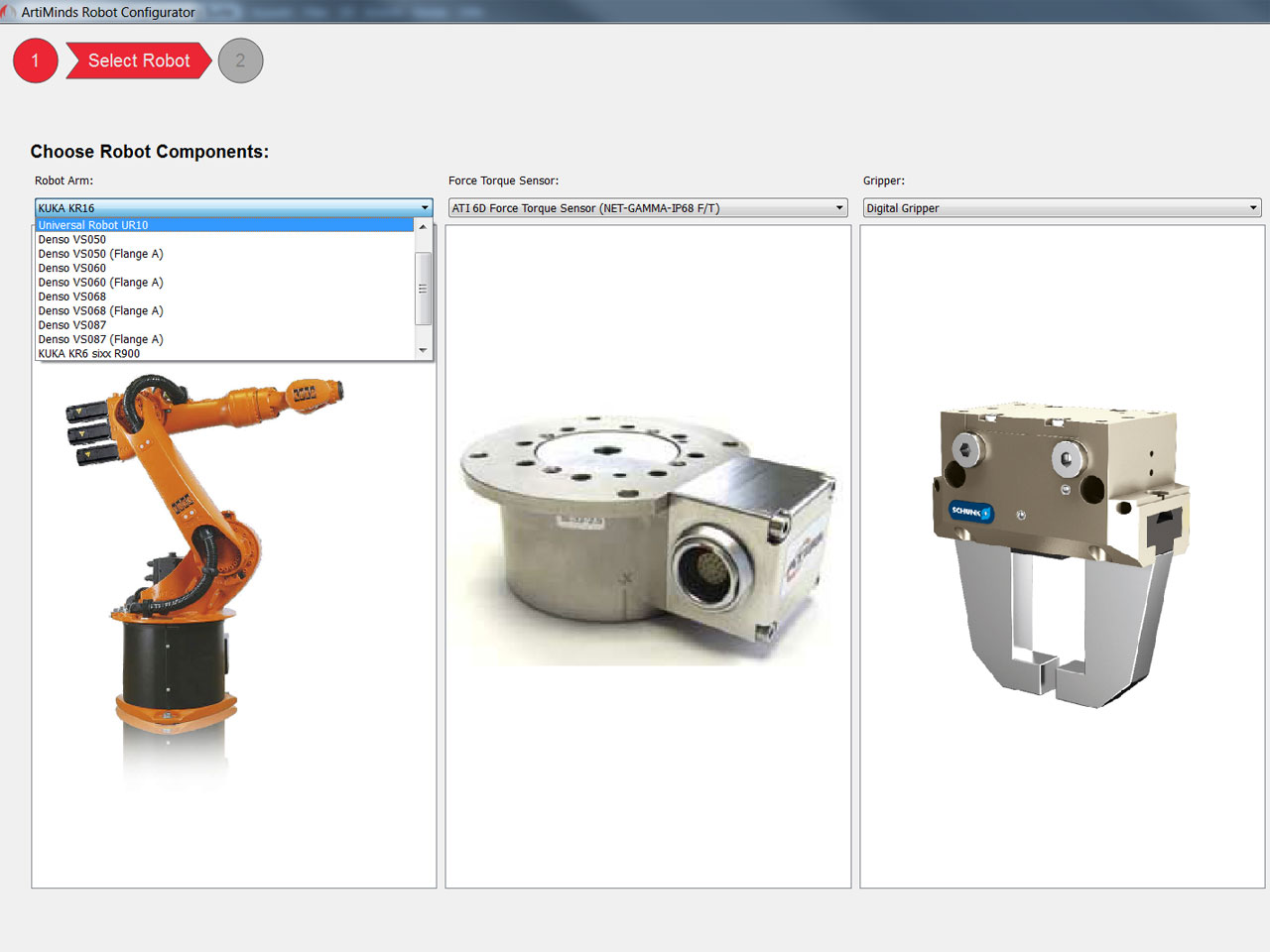

As a holistic robotics partner, ArtiMinds is not only a software provider, but also a leader in the development of innovative and sophisticated robot automation solutions, whether as a partial or overall concept.

Trust in our expertise in the area of

> Process Development

> Feasibility Studies

> Prototyping

> Project Support & Engineering

> Programming

Get in touch and start your automation project with ArtiMinds.