Robotics Blog

Industry topics and ArtiMinds news

January 18, 2021

Fast set up of automated grinding processes using ArtiMinds RPS and ArtiMinds LAR

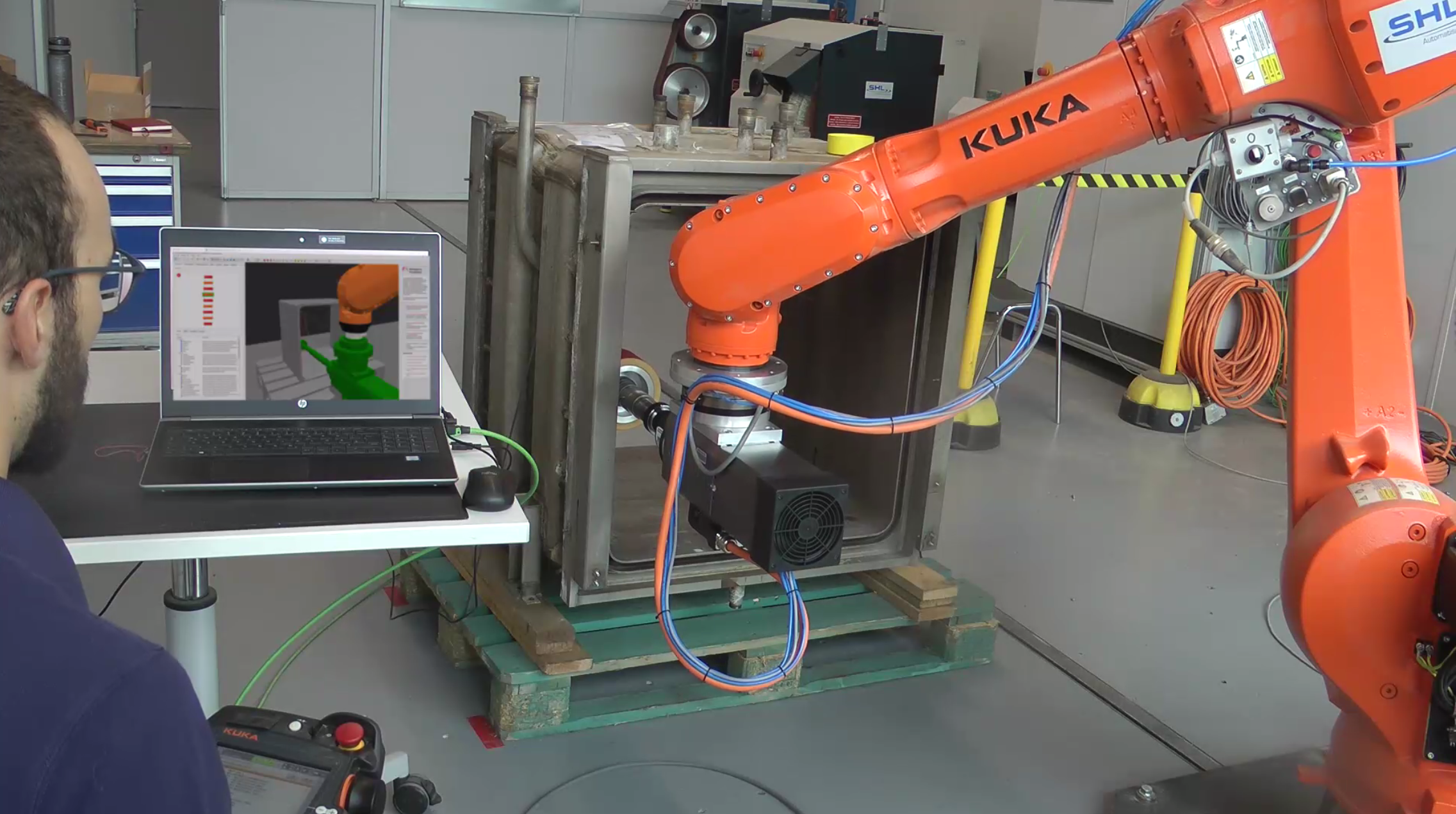

For a customer project, SHL, an expert in the development of flexible robotic cells in the field of surface finishing, was asked to carry out trials for the automated grinding of medical disinfectors. SHL decided to carry out a project with ArtiMinds Robotics to test the suitability of force/torque sensors for the required adaption of the system.

January 7, 2021

Robot-supported ultrasonic defect testing and quality control

Using ultrasonic, defects in components and inhomogeneities can be located. Robot-supported automation can reduce test costs and test time and make measurements reproducible. ArtiMinds RPS supports companies in programming a force controlled application with less effort and in automating path planning for complex components.

December 19, 2020

Season Greetings

In this challenging year, we would like to thank you for your trust and the good cooperation and we wish you and your family a happy holiday season as well as a healthy and successful start into the new year 2021!

“Happiness often comes from paying attention to small things,

often misfortune is caused by neglecting small things.”

Wilhelm Busch

Kind regards, Your ArtiMinds team

November 19, 2020

Hardware independent robot programming

Force/torque sensors are proven tools in many robot applications, e.g. to compensate manufacturing

tolerances or wear and thereby increasing the robustness. For this purpose, robot manufacturers offer

extensive technology packages for their controllers, but their use requires special expertise and extensive

programming knowledge.

With ArtiMinds RPS +Force you can implement robot applications with force/torque sensors in a very short time, even without special knowledge. Since the robot code is generated automatically and, during online mode, there is a direct connection to the robot controller, you can test solution approaches such as probing, searching for holes or torque balancing live on the robot without high programming effort – and thus save a lot of time during process development.

ArtiMinds RPS +Force supports a wide range of force/torque sensors and offers over 25 tailored building blocks and wizards, as well as the extension of the robot’s live data with sensor measurement data.

The ArtiMinds e-paper shows which manufacturers, force/torque sensors and grippers are supported.

November 9, 2020

Release of ArtiMinds RPS 1.9.9

The latest ArtiMinds RPS version 1.9.9 is now available for installation. The major changes include highlights such as the integration of three new KUKA robot models as well as the implementation of two new templates (Switch template and Dialog builder template).

You can find the entire changelog with all changes and bug fixes in the ArtiMinds RPS directory.

November 06, 2020

Special webinar issue “surface processing”

On December 1 and 2 we are offering new free webinars focussing on “robot-supported surface processing” as special topic. With reference to industrial practical examples, we show the challenges in grinding, polishing and deburring and how these processes can be automated easily and robustly with robots.

November 04, 2020

New ArtiMinds FAQ section

In our new FAQ section we answer the most important questions about the ArtiMinds software solutions, our services, applications and technical requirements.

October 22, 2020

B/S/H presentation on “Integrated Robtics and Assembly Planning”

From 3 to 4 November Siemens is organizing a digital event called “Realize Live Europe”. The focus of this event is to learn more about approaches and innovations that drive digital transformation.

ArtiMinds customer B/S/H, one of the leading home appliance manufacturers worldwide, will be talking about how B/S/H realizes a higher process efficiency through integrated robotics and assembly planning and which role ArtiMinds plays in this context.

As a Siemens partner ArtiMinds, Siemens and B/S/H are working very closely and successfully together since several years.

Find more information on the event website.

October 2, 2020

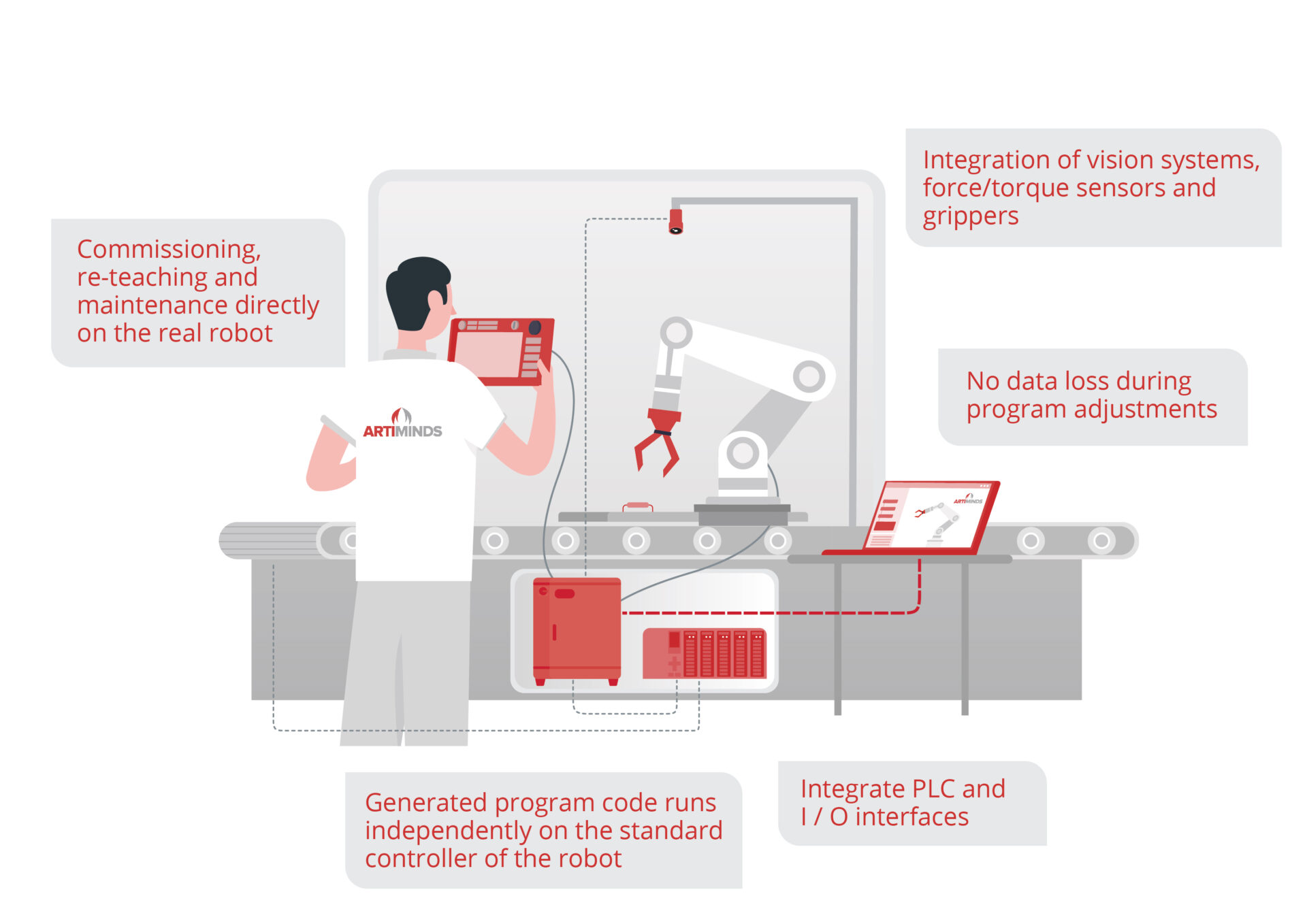

Why ArtiMinds - our software at a glance

ArtiMinds RPS and LAR support the user in all phases of his robot application, from planning and programming to commissioning and operation.

Our new infographics show how ArtiMinds can be consistently integrated into new and existing automation systems as well, what added value and advantages the software creates and how you can still remain independent in your work and processes.

September 14, 2020

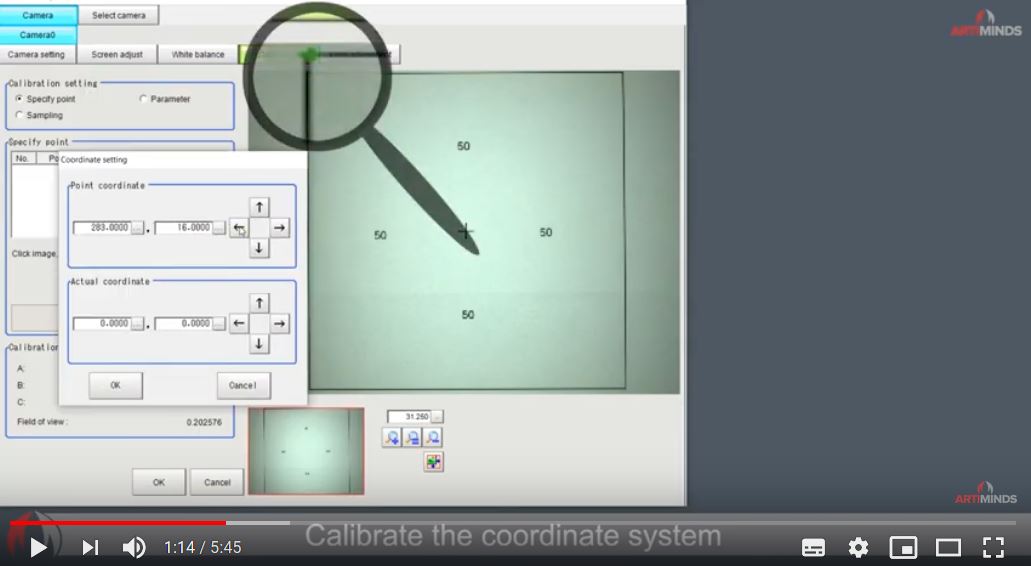

New video tutorial: Setting up an OMRON FHV smart camera

With the new release V1.9.7 the OMRON FHV smart cameras for universal robots are supported. Find out how to configure the OMRON camera for your robot application with ArtiMinds RPS in our new video tutorial.

September 14, 2020

Release of ArtiMinds RPS 1.9.7

The latest ArtiMinds RPS version 1.9.7 is now available for installation. The major changes include highlights such as the extension of the supported hardware by OMRON FHV smart cameras, the possibility to blend between additional motion types and the visualization of “blended” 3D paths.

You can find the entire changelog with all changes and bug fixes in the ArtiMinds RPS directory.

September 1, 2020

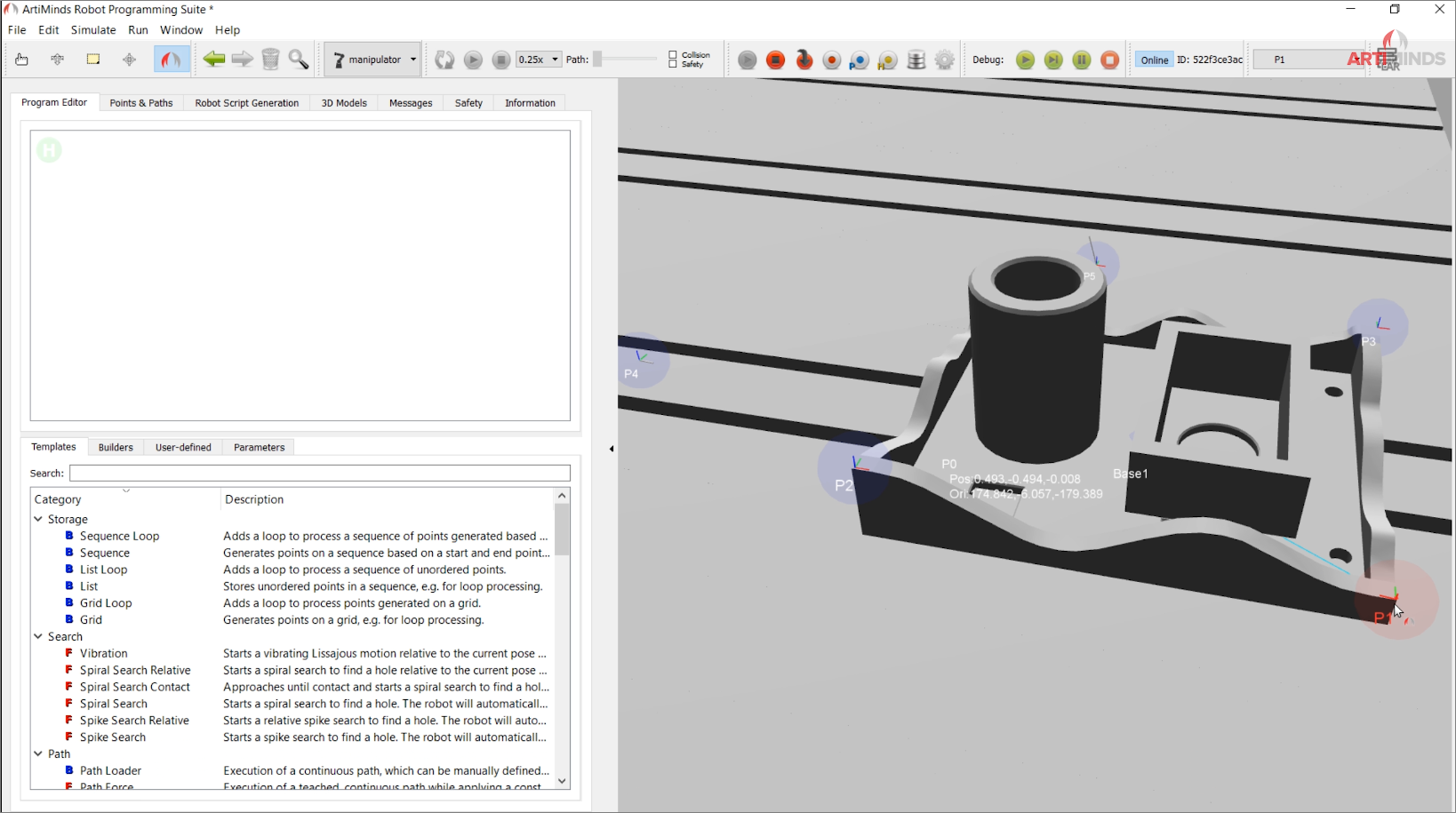

TechTip CAD2Path: Why the orientation of the TCP is important, that all points can be reached

The CAD2Path feature allows to import CAD models into ArtiMinds RPS, thereby minimizing the programming effort for components with complex geometries.

What can you do if a point theoretically in reach of the robot is still marked as not reachable after the path import? Our current TechTip shows how you can solve this accessibility problem in just a few steps and what role the orientation of the TCP plays.

August 21, 2020

New tutorial: Calibration of a 3D CAD model to the real work piece

This tutorial shows how to match the position of the real work piece with the path generated via the CAD2Path function in ArtiMinds RPS. Thanks to the combination of online and offline programming the exact position of the 3D CAD model can easily be calibrated in a few steps.

This approach can also be used for the calibration of 3D models in general, e.g. for workplace digitization.

August 14, 2020

New ArtiMinds e-paper: Standardized robot programming

Since ArtiMinds is compatible with numerous industrial robots, force-torque sensors, grippers and vision systems, you are able to program your robot application independently of manufacturers and you remain flexible in the selection of the hardware that suites best for your needs. Robot programs created with ArtiMinds can also be transferred to another robot at any time.

How does consistent and standardized programming with ArtiMinds work?

The e-paper gives an overview of the supported robots and peripheral devices and provides information on the products and their fields of application.

August 5, 2020

Release of ArtiMinds RPS 1.9.6

The latest ArtiMinds RPS version 1.9.6 is now available for installation. The major changes include highlights such as the possibility to add (individual) names and types of motion templates to the generated code and the addition of new builders templates for setting and reading variables.

You can find the entire changelog with all changes and bug fixes in the ArtiMinds RPS directory.

July 16, 2020

Standardized robot programming

Today, robots can already do more than one might think. You just have to “teach them.” But it is exactly this teaching, i.e. robot programming, that is the reason why many companies shy away from using robots. Small and medium-sized companies dread the large programming effort, while large companies are always troubled by the lack of standardization.

How can you overcome these hurdles?

June 29, 2020

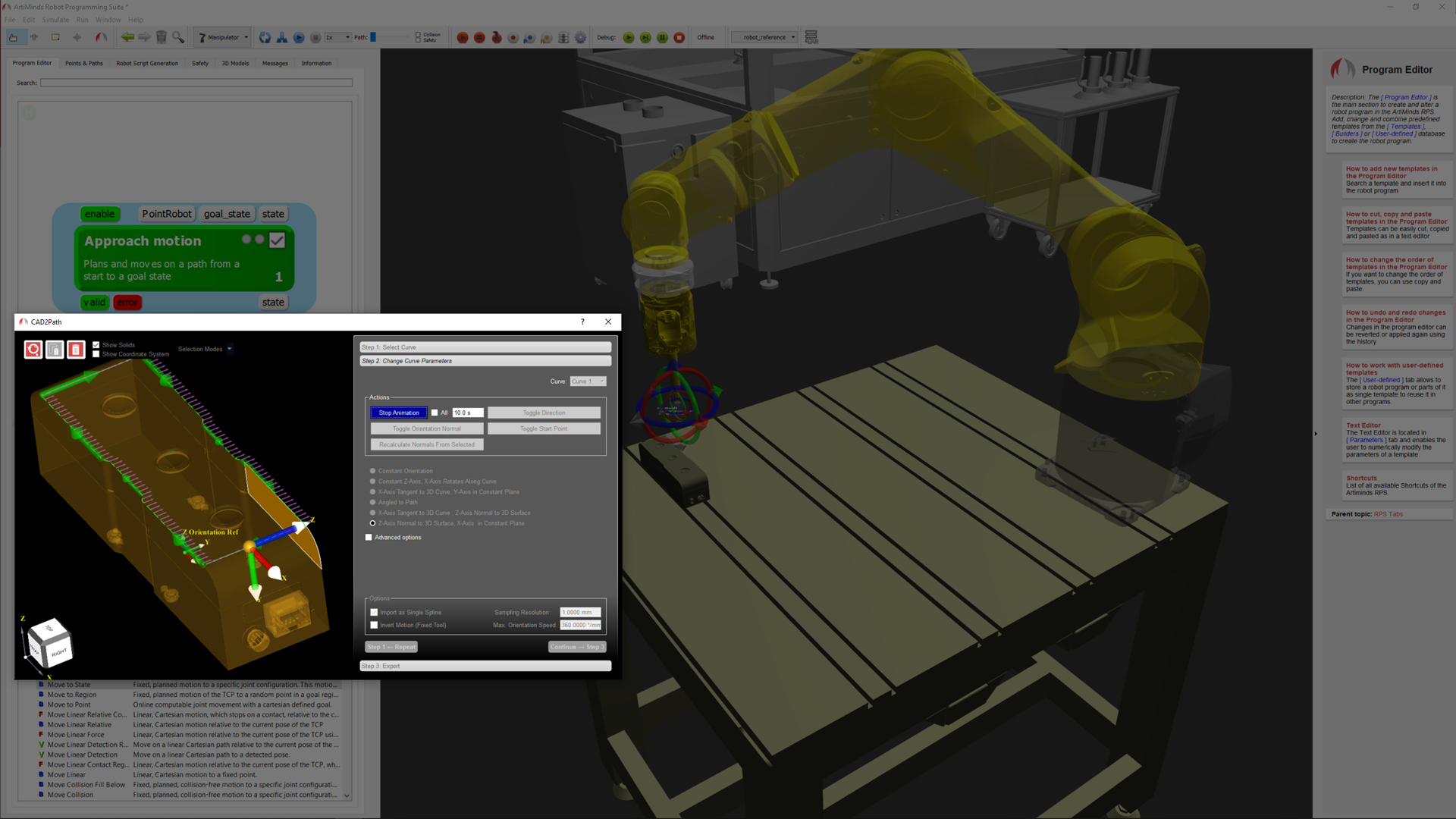

TechTip CAD2Path: Avoiding incorrect calculations of the surface normals

The CAD2Path feature minimizes the programming effort for components with complex geometries and allows you to import CAD models into ArtiMinds RPS. Depending on the shape of an object errors may occur if the automatic calculation assumes an incorrect reference surface.

Our current TechTip shows how this can be easily avoided.

June 23, 2020

New online seminar dates: automating with robots

Would you like to produce more efficiently and automate industrial processes with robots?

Then our free online seminar series “Automating with robots” offers you first helpful insights and tips.

June 17, 2020

Release of ArtiMinds RPS 1.9.4

The latest ArtiMinds RPS version 1.9.4 is now available for installation. The major changes include highlights like the addition of the new template “Move to Point”, the addition of a second simulation function as well as the improvement of the link between Cartesian key positions of templates and 3D points in the Point Tool.

You can find the entire changelog with all changes and bug fixes in the ArtiMinds RPS directory.

June 10, 2020

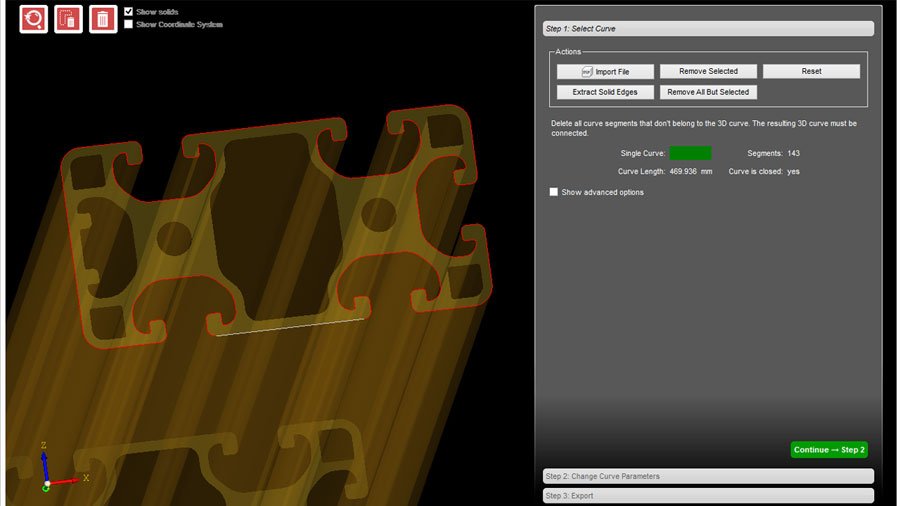

Traversing complex paths with little programming effort

Would you like to deburr, polish or apply adhesive to components with complex geometries with a robot? The CAD2Path feature reduces the programming effort required for such applications to a minimum by allowing you to import CAD models of the part into the ArtiMinds Robot Programming Suite (RPS). The software then automatically extracts the model’s edges.

After the desired path has been selected, it can be modified and the curve parameters can be set, i.e. the specification of how the TCP should move around the object. Finally, the (complex) trajectory is imported effortlessly into the robot program as a path.

The CAD2Path feature supports the formats STEP, IGES, BREP as well as BINBREP.

May 28, 2020

New Case Story of ZF Friedrichshafen

Program and simulate robot applications independently of manufacturers, reduce maintenance costs and alleviate the lack of skilled workforces.

ZF, one of the largest automotive suppliers worldwide, explains in our new best practice use case how they succeed thanks to ArtiMinds.

May 11, 2020

Release of ArtiMinds RPS 1.9.3

The latest ArtiMinds RPS version 1.9.3 is now available for installation. The major changes include highlights like the extension of of the hardware support for KUKA, Zimmer, ATI and UR eSeries as well as the extension of the wizward for the Grid template.

You can find the entire changelog with all changes and bug fixes in the ArtiMinds RPS directory.

May 1, 2020

Free Webinars: automating with robots

Would you like to produce more efficiently and automate industrial processes with robots?

Then our free webinar series “Automating with robots” offers you first helpful insights and tips.

April 10, 2020

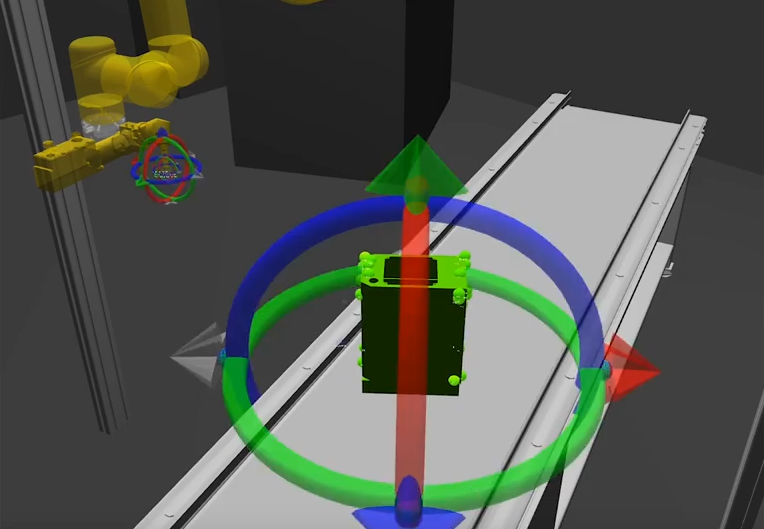

Robot cell design via manipulability calculation

When designing a robot cell, it is essential to be able to simulate which points can´t be reached by a robot and which points may be difficult to reach. The ArtiMinds RPS feature manipulability calculation supports the user by color-coding the degree of how good an individual point can be reached by the TCP.

March 27, 2020

automatica is postponed - new date in December 2020

The trade fair for robotics and automation will be postponed due to the current corona situation and will take place from 8 to 11 December 2020. ArtiMinds Robotics is looking forward to welcoming you in Munich in hall C6, booth 306.

March 23, 2020

Best Practice: force controlled polishing with robots

Visomax Coating GmbH has developed a solution to automate the force-controlled polishing of painted surfaces with robots using ArtiMinds RPS.

February 21, 2020

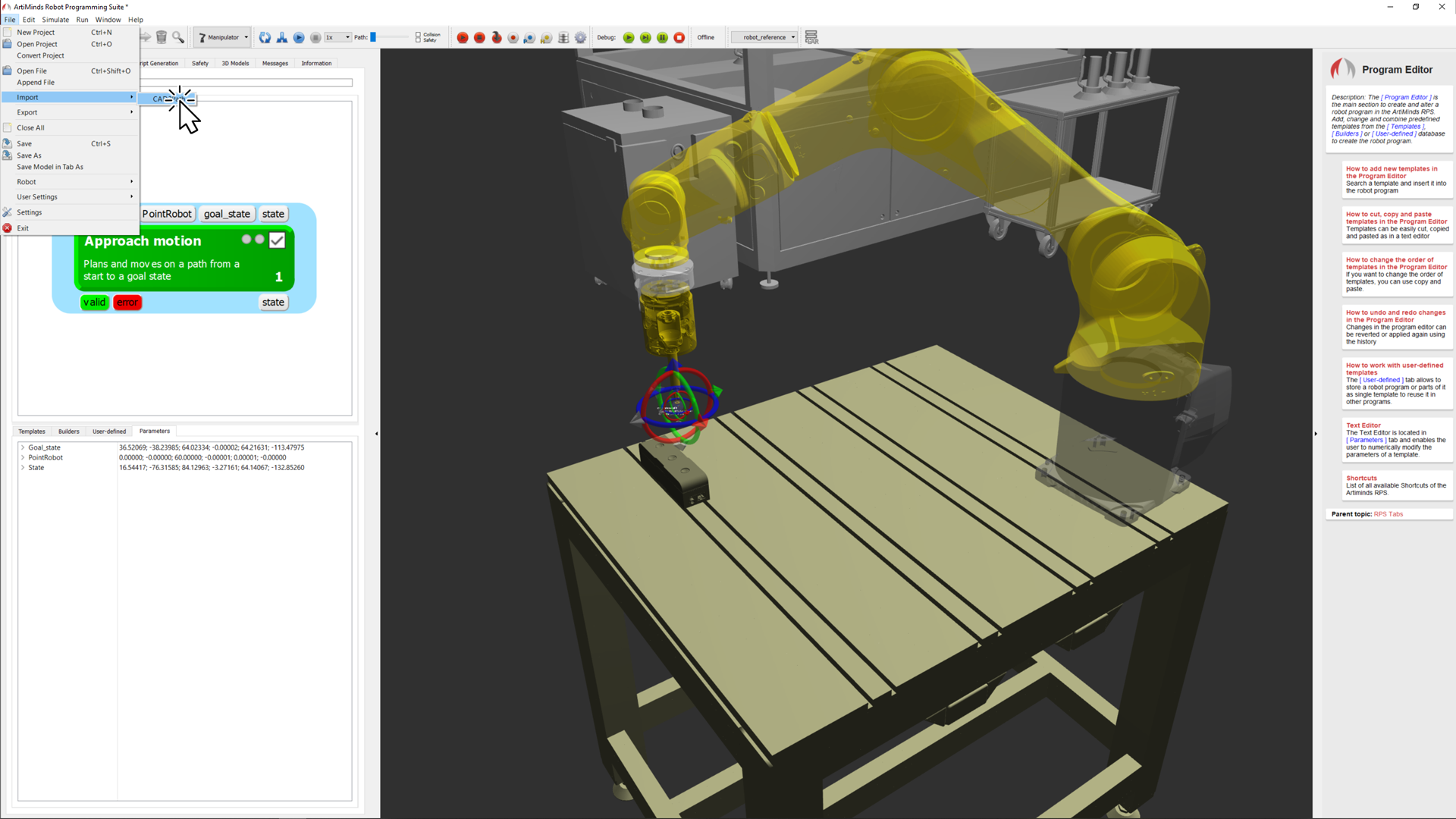

Release of ArtiMinds RPS 1.9

The latest ArtiMinds RPS version 1.9 is now available for installation. The major changes include highlights like a permanently visible help window on the right hand side of the screen, which will dynamically display entries of the ArtiMinds RPS online help depending on the current user interaction and support of Fanuc iRVision cameras.

You can find the entire changelog with all changes and bug fixes in the ArtiMinds RPS directory.

February 10, 2020

Cooperation of ArtiMinds with Wibu-Systems

ArtiMinds uses CodeMeter to protect and license the Robot Programming Suite software. In a video interview, CEO Dr. Sven Schmidt-Rohr explains where he sees the advantages of the cooperation with Wibu-Systems.