Electronics assembly

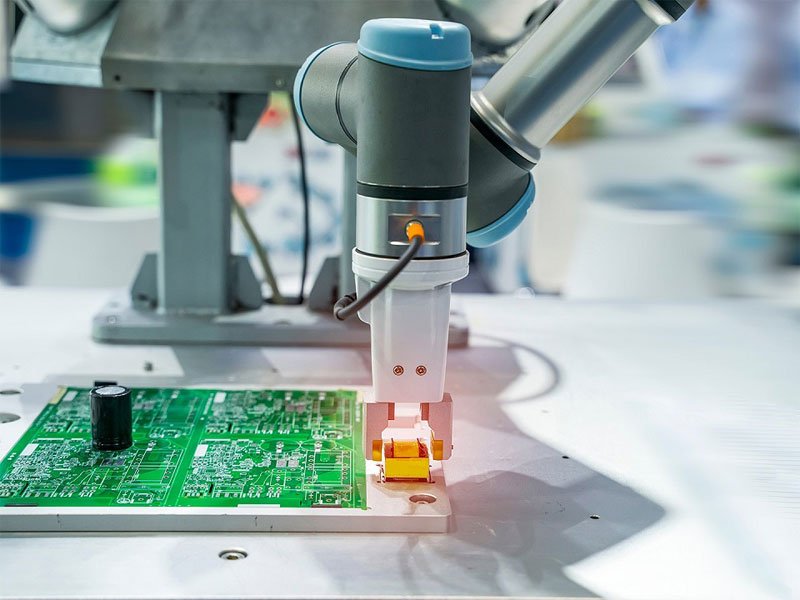

Robustly automate the precise handling of sensitive components

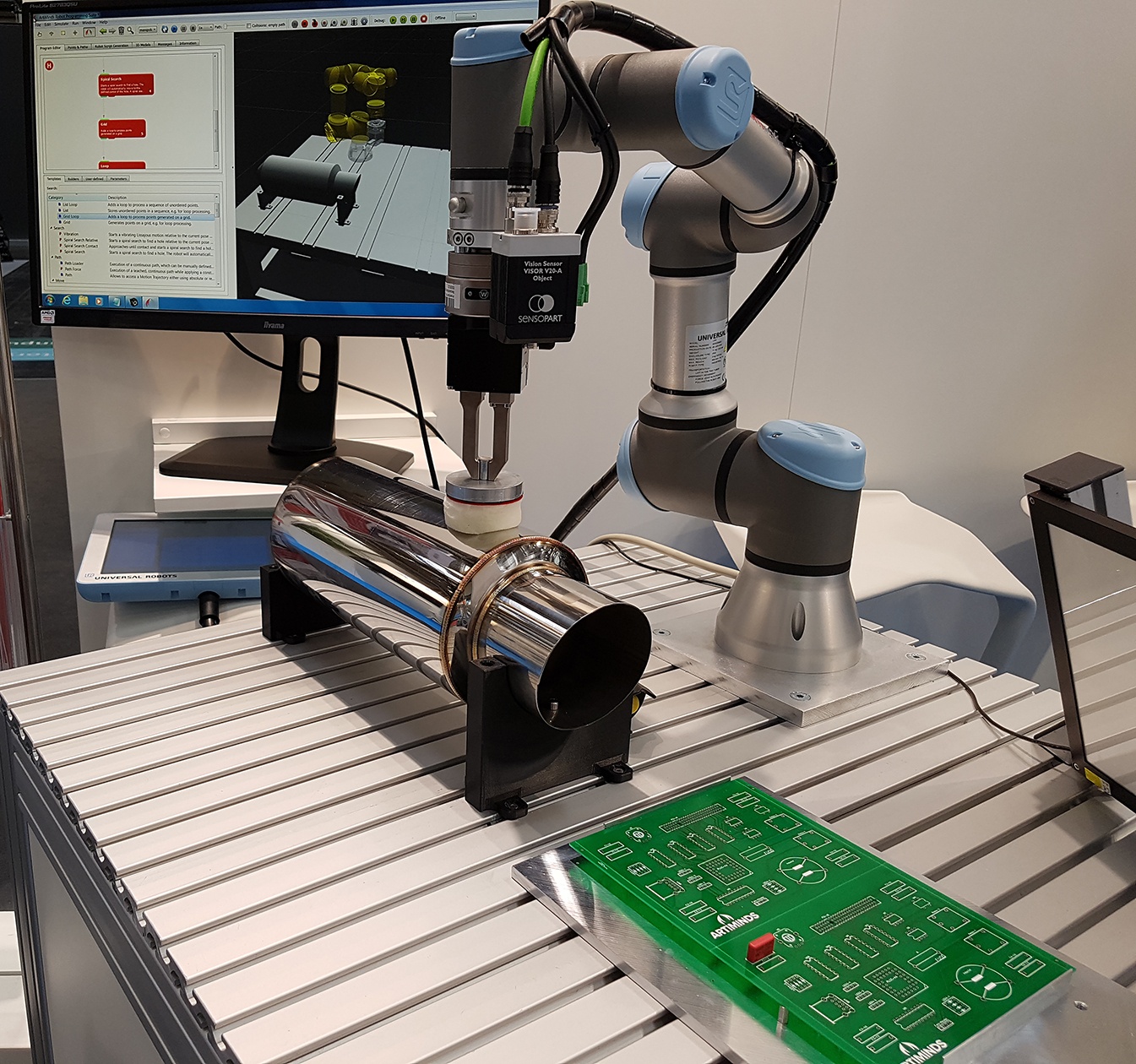

With the software ArtiMinds RPS, nearly all electronics assembly processes can be automated. Sensor-based robot programs using vision systems or force sensors address the pervasive process variances prevalent in electronics assembly which are caused by flexible materials like soft plastics and rubber as well as by tolerances resulting from processes like soldering or adhesion. The process variances can be analyzed using ArtiMinds LAR to pinpoint part-specific problems and optimize the production.

The automated manufacturing of electronic components has so far been associated with considerable difficulties. This was particularly evident in the precise handling of flexible, often sensitive components. Also managing a high variability at low volumes was not that easy. Most of these processes can now be implemented easily with the ArtiMinds RPS and the use of visual and tactile sensing.

You would like to implement a robotics project? Use our free robotics checklist to select the right hardware & software and to organize the most important project steps!

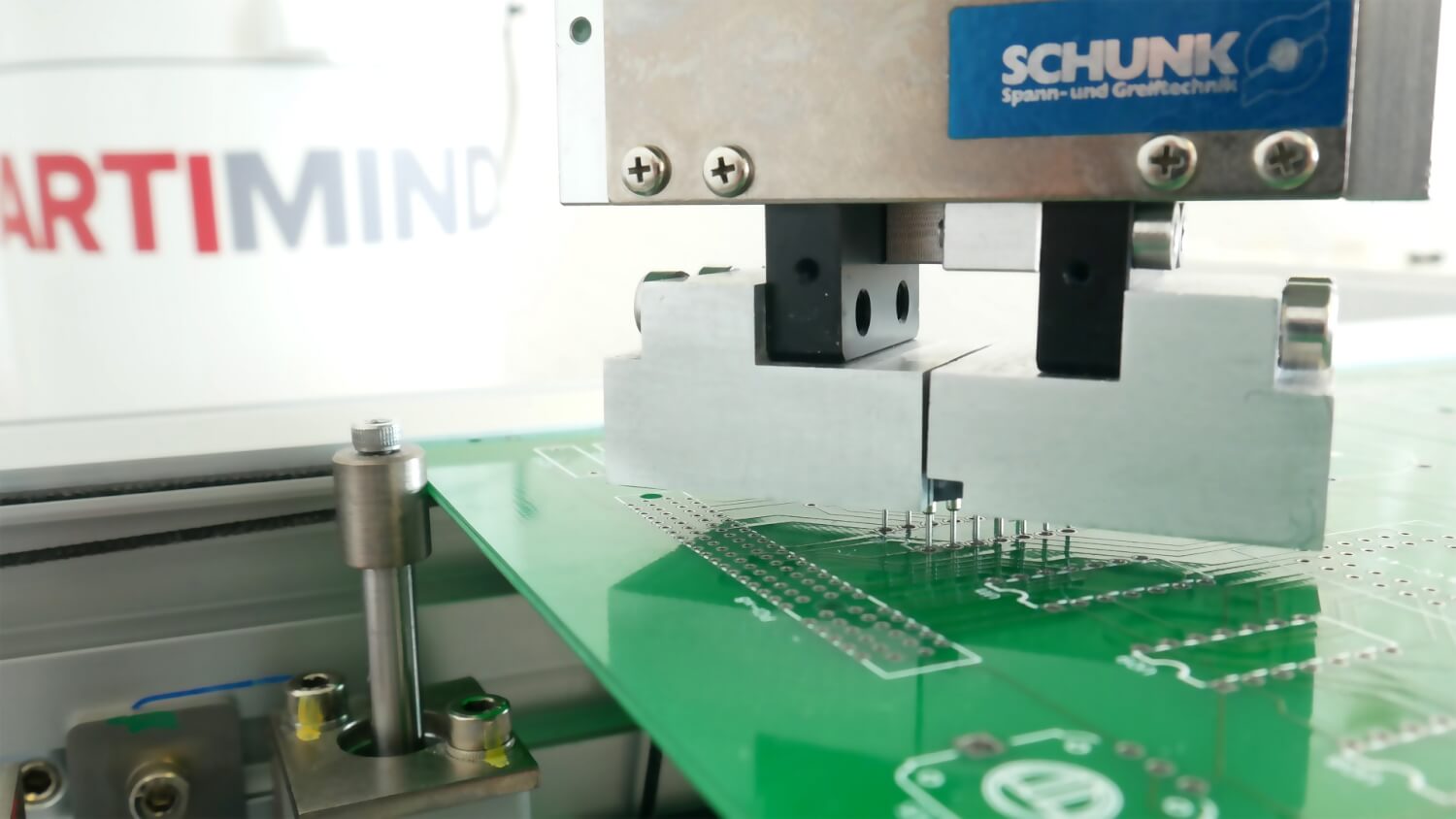

Application example: THT assembly

If you, for example, want to assemble circuit boards with wired components such as capacitors, coils, connectors or switches, this is usually done using the manual THT method. Here, the sensitive, flexible components are inserted through contact holes into the circuit board and then soldered. Due to the resilience of metal parts and plastics, as well as the tolerances of the component housings and the high umber of variants of electronic components, the use of automated solutions has mostly been unprofitable.

ArtiMinds RPS supports you in automating THT assembly with the help of robots. By means of force-controlled movements such as the controlled insertion or scanning of surfaces, the industrial robot can also be used for such filigree tasks. In particular, sensor-adaptive applications and the integration of grippers, camera systems and force-torque sensors can be implemented quickly and robustly with ArtiMinds RPS.

.

Further application examples:

- Assembly of cables, plugs and wires >>MORE

- Automated screw fastening

- Placing of THT components

- Mounting of PCBs and casings

- Placing and tightening screws

You want more? We support you in the robot-based automation of your electronics assembly processes

You want more? We support you in the robot-based automation of your electronics assembly processes

You want to integrate new and flexible automation processes into your workflows and need e.g. support in the automation of a THT assembly process? Our Automation Engineering team of engineers and robotics experts will be happy to advise you and take over tasks such as the prototyping.

ArtiMinds is a leader in the development of innovative and sophisticated robot automation solutions, whether as a partial or overall concept. Our experts will be happy to provide you with advice and support from conceptual design to implementation.

Get in touch – our specialists will provide you with comprehensive advice and develop an initial concept or carry out a feasibility study in close cooperation with you.

Industrial examples – short videos of real customer applications

ARTIMINDS – YOUR HOLISTIC ROBOTICS PARTNER FOR ELECTRONICS ASSEMBLY

OUR OFFERING:

ROBOTICS SOFTWARE

ROBOTICS ENGINEERING

Why ArtiMinds Robotics?

ArtiMinds RPS has unique features that make previously impossible solutions possible. Talk to our experts about your automation project, we will be happy to support you! Be ahead of the competition with ArtiMinds Robotics.

>>READ THIS BLOG POST: ArtiMinds RPS & LAR at a glance

Highlights of ArtiMinds RPS for electronics assembly:

- Easy integration of vision systems and force-torque sensors

- Suitable for high-mix low-volume

- In-depth analysis of supplied parts

Decide for a robust, flexible and affordable automation solution – choose ArtiMinds. See for yourself in an online demo!

>>THAT´S WHAT OUR CUSTOMERS SAY<<

Just get in touch. Our application experts will be happy to advise you on your individual automated robot application. Make an appointment right now for an online demo and learn how ArtiMinds can help you to implement a flexible robotic automation project.

Browse through our Robotics Blog or FAQ section and learn interesting facts about ArtiMinds RPS & LAR. Our Download & Press area provides further information. Or sign up to our newsletter for regular news and ongoing updates.

FREE ONLINE DEMO: GET STARTED AND LEARN MORE ABOUT ROBOT-BASED AUTOMATION

In just a few minutes, we will show you how to plan, program, operate, analyze and optimize robot applications cost-efficiently, intuitively and easily with ArtiMinds RPS.

The non-binding free online demo is the perfect way to get a first impression of the software, the application portfolio and if it suits your needs.